When using heap leaching to extract silver from lead-zinc ore, it is first necessary to clarify the occurrence state of silver (such as independent silver minerals, isomorphous substitution, or inclusions) through methods such as XRD and SEM-EDS, and analyze the chemical composition (Pb, Zn, S, and interfering element content) and intercalation characteristics of the ore to evaluate the feasibility of leaching. Subsequently, cyanidation conditions are optimized through stirred leaching experiments to ensure efficient dissociation of silver while inhibiting the dissolution of lead and zinc. Finally, column leaching experiments are combined to verify the heap leaching permeability and silver recovery rate, taking into account both economic and environmental requirements.

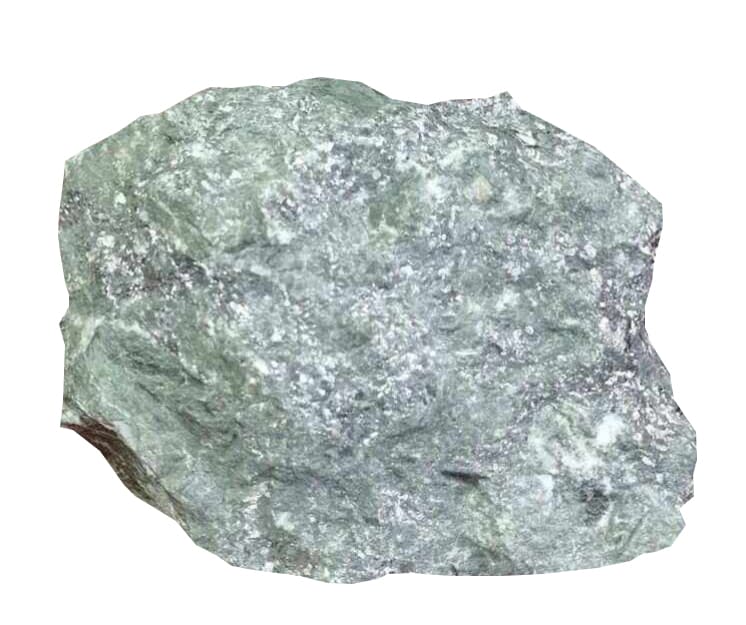

Lead-zinc-silver Mineral Phase Analysis

Occurrence of Silver (Key Phase Analysis)

Independent Silver Minerals

- Common minerals include: argentite (Ag₂S), argillite (AgCl), native silver (Ag⁰), (Ag,Cu)₁₆Sb₂S₁₁, etc.

- The presence and distribution of silver should be determined using X-ray diffraction (XRD), electron microprobe microscopy (EPMA), or mineral microscopy.

Isomorphic Substitution

- Silver may substitute for Pb⁺/Zn⁺ in galena (PbS) or sphalerite (ZnS). Trace silver distribution should be analyzed using inductively coupled plasma mass spectrometry (ICP-MS) or scanning electron microscopy-energy dispersive spectroscopy (SEM-EDS).

Inclusions or adsorption

- Silver may be encapsulated in gangue minerals (such as quartz and pyrite) in the form of nanoparticles or adsorbed on the surface of clay minerals. This requires verification through selective dissolution experiments or high-resolution transmission electron microscopy (HRTEM).

Ore Chemical Composition Analysis

- Major Elements: Pb, Zn, Fe, and S content (determines acid consumption and neutralizer dosage).

- Interfering Elements: Cu²⁺ (consumes cyanide), As/Sb (may form harmful compounds), and carbonate minerals (such as calcite, which can cause pH to become uncontrolled).

- Degree of Oxidation: Sulfide ore (requires oxidation pretreatment) or oxidized ore (may be directly cyanide).

Cyanide Leaching Conditions

In zinc oxide ores, zinc readily dissolves in the cyanide solution. Smithsonite (ZnCO₃), zincite (ZnO), and hydrozincite (3ZnCO₃·2H₂O) are particularly soluble in the cyanide solution, consuming significant amounts of cyanide. Furthermore, the resulting Zn(CN)₂ deposits on the surface of the gold particles, hindering the dissolution of silver.

Minor lead content in the ore can be beneficial for the cyanidation of gold and silver. Lead can counteract the harmful effects of alkali metal sulfides in the cyanide solution. When leaching argentite (AgS), lead salts can precipitate S₂- from the generated Na₂S as PbS, thereby promoting the dissolution of silver in the cyanide solution. However, this effect is not present in complex silver sulfate ores.

Excessive lead can have a certain impact on the leaching rate of gold and silver, decreasing with increasing lime dosage.

The following measures can be taken to treat silver-containing ores:

First, leaching with a high-concentration cyanide solution (0.2-0.6% NaCN) ensures the dissolution of silver.

Second, the heap leaching ore must have good permeability and porosity to provide the oxygen required for silver dissolution.

Key indicators

Mineral Ore Type | Cyanide Difficulty | Pretreatment Requirements |

Native silver/free silver | Easily soluble | Direct cyanidation is recommended |

Argentite (Ag₂S) | Moderately soluble | Requires oxidation roasting or MnO₂-assisted leaching |

AgCl | Easily soluble | Avoid excessive Cl⁻ concentrations that interfere with subsequent processing. |

Antimony/silver arsenide | Poorly soluble | Requires high-temperature, pressure-assisted oxidation. |

Interferences with Elemental Analysis

- Lead (galena): Consumes cyanide to form Pb(CN)₂, requiring lime inhibition (pH > 10.5).

- Zinc (sphalerite): Passivates under alkaline conditions, but generates Zn(CN)₄²⁻, consuming cyanide.

Heap Leaching Process For Extracting Silver From Lead-zinc Ore

Heap leaching is a cost-effective hydrometallurgical method for extracting silver from low-grade lead-zinc ores. The process involves stacking crushed ore on an impermeable pad and applying a cyanide solution (or an alternative) to dissolve silver, which is then recovered from the pregnant leach solution (PLS). Below is a step-by-step technical breakdown:

Ore Pre-treatment

The purpose of pre-treatment is twofold: first, to reduce the ore to a specific particle size, ensuring thorough contact between the cyanide leaching solution and the silver; second, to impart adequate permeability to the ore, enabling uniform permeation of the leaching solution through the heap.

Pre-treatment methods include crushing to an appropriate size for heap leaching, or crushing followed by pelletization before heap leaching. For ores generally suitable for heap leaching, crushing to a size between 30mm and 10mm is recommended.

Heap Construction

Heap construction is a critical step in heap leaching. The method employed affects the heap’s permeability and the uniform distribution of coarse and fine particles, directly influencing silver leaching rates.

Pile construction may be performed manually or mechanically.

During construction, avoid crushing ore to prevent secondary slime formation, localized compaction, and particle segregation. Ensure uniform particle size distribution, good permeability, and aeration throughout the pile. This allows cyanide solution and oxygen to flow freely through all areas, preventing channeling and stagnation zones during leaching.

Common heap construction methods include:

- Separate heap construction

- Layered heap construction

- Segmented layered heap construction

Heap height varies with project scale, typically ranging from 2 to 5 meters.

Spray Leaching

Before spraying cyanide solution onto the ore heap, it should undergo water washing and alkali washing. Cyanide solution spraying should commence only when the washing solution pH reaches 9.5 to 11.

1. Spray Equipment

Uniform liquid distribution is a key factor in enhancing leaching efficiency. Distribution methods include spray distribution and drip distribution. Regardless of the method, the leaching solution must fully cover the entire ore heap. Flow rates at all surface points should be balanced, with minimal evaporation and drift loss. Distribution systems must use corrosion-resistant materials, such as polyvinyl chloride (PVC) plastic.

2. Leaching

(1)Ore Washing

To reduce cyanide and alkali consumption, alkali washing (or water washing followed by alkali washing if necessary) should precede cyanide solution spraying on the ore heap. CaO aqueous solution or NaOH aqueous solution may be used. Lime solution is inexpensive but requires longer leaching time and is prone to calcium scaling. NaOH solution offers a shorter leaching time but is costly. When the pH of the solution flowing from the heap reaches 9.5–11 (typically after 3–5 days), spraying with a mixture of NaCN and alkali can commence.

(2) Spray Leaching

Throughout heap leaching, maintain optimal concentrations of cyanide, alkali, and oxygen.

Sodium cyanide concentration: Typically, the control leaching solution sodium cyanide concentration is between 0.02–0.1%.

NaCN concentration should be controlled in phases: typically starting at 0.08–0.1%, mid-stage at 0.05–0.06%, and late stage at 0.02–0.05%. During production, regularly measure cyanide concentration and leachate pH, adjusting promptly—generally 1–2 times daily.

(3) Spray Intensity

Spray intensity is typically 10–20 liters/m².

Lower values apply to large, poorly permeable ore bodies, while higher values are more suitable for smaller, more permeable ones. Continuous or intermittent cyanide solution spraying may be used; intermittent spraying facilitates oxygen replenishment and enhances gold/silver leaching. Spray for 2 hours, pause for 1 hour, then resume spraying.

When spraying alkaline cyanide solution, regularly inspect nozzles and pipelines for blockages. Address areas with insufficient coverage to ensure the solution reaches every location, guaranteeing silver leaching efficiency.

To prevent scaling in nozzles, pipelines, and ore piles, add appropriate scale inhibitors to the cyanide leaching solution.

(4)Heap Leaching Duration

The required heap leaching time depends on factors such as ore properties and particle size, determined by testing. Typically, it ranges from 1 to 2 months, with longer durations possible up to 3 months. Spraying can be stopped when the gold grade in the leachate falls below 0.1 g/m³.

The leached gold and silver-bearing solution flows into the precious liquid pool. Gold and silver are recovered using methods such as carbon adsorption, zinc displacement, or direct electrowinning.

Gold & Silver Recovery from Heap Leaching Precious Metals

For precious metals with high gold and silver grades and large volumes, zinc displacement precipitation is generally used. Activated carbon adsorption is not suitable because silver competes with gold for adsorption, reducing its adsorption capacity.

For medium-scale heap leaching operations with moderate gold and silver contents, activated carbon or resin adsorption, desorption-electrodeposition processes can be used to recover precious metals.

For heap leaching precious metals with high gold and silver concentrations (over 30-50 mg/L), gold and silver can be directly extracted by electrodeposition after clarification.

Activated carbon adsorption is a widely used heap leaching method due to its simplicity and low investment costs.

When the silver content in the gold-bearing precious metals is high, sodium sulfide can be used to precipitate the silver first, releasing it as silver sulfide. Before the precious metals enter the adsorption process, filtration is used to remove the silver (silver sulfide precipitation) from the precious metals. This prevents the high silver ion concentration from affecting the activated carbon’s adsorption of gold during the carbon adsorption process, thereby increasing the carbon’s gold adsorption capacity and reducing the desorption and electrodeposition processing volume, thereby lowering production costs.

Conclusion

Heap leaching is viable for oxidized or partially oxidized lead-zinc ores with Ag >50 g/t. For refractory sulfides, consider pre-oxidation (bio/chemical). Pilot testing (500–1000 kg) is mandatory to optimize:

- Cyanide dosage (avoid overuse)

- Irrigation rate (prevent saturation)

- Ag recovery method (Merrill-Crowe vs. carbon)