Introduction: Potential and Challenges of African Wolframite Resources

Africa is a significant global source of wolframite (black tungsten ore), primarily distributed in countries such as DR Congo, Rwanda, and Nigeria. However, these regions commonly face challenges such as low ore grades, fine mineral dissemination, and outdated beneficiation technology. Due to its low cost and operational simplicity, gravity separation has become the mainstream method for wolframite processing in Africa. This article combines case studies from key resource-rich countries to provide a detailed breakdown of gravity separation flowsheets and optimization strategies tailored to African wolframite ores.

APT Long-Term Contract Prices Surge Significantly, Tungsten Market Repeatedly Hits New Highs

Recently, tungsten ore prices have repeatedly hit new highs, especially the long-term contract price of APT (ammonium paratungstate), which has surged, creating a severe imbalance between supply and demand. According to the latest SMM Tungsten Daily report, the tight supply-and-demand situation in the tungsten market is unlikely to ease in the short term. Specifically:

- Upstream mines and APT turnover are tight, with some mines having already used up their initial quotas, resulting in some companies being unable to ship, further exacerbating the supply and demand imbalance.

- Suppliers are unwilling to sell, coupled with high production costs, driving market prices up continuously.

- Some domestic cemented carbide companies are facing financial and cost pressures, and industry orders are gradually concentrating on medium and large-sized enterprises.

According to forecasts, the supply of tungsten concentrate will remain tight, especially since the quota allocation policies for mines in some countries are still not unified, and new quotas require policy guidance.

In the short term, the tungsten industry chain exhibits the dual characteristics of high prices and high risks. Downstream cemented carbide companies are facing increasing procurement pressure, and driven by rigid demand, the supply of raw materials is expected to remain tight.

Industry Recommendation: Monitor developments in the tungsten supply chain, particularly mine operations, transportation status, and contract guidance policies for upstream tungsten industries. Tungsten prices are expected to continue rising, especially in the production of high-end cemented carbides and powder metallurgy.

Major African Wolframite-Producing Countries and Ore Characteristics

Overview of African Countries With Tungsten Resources

Within the African continent, the following countries are relatively active in tungsten resources and deserve close attention:

- Rwanda

As an East African country, Rwanda has well-defined tungsten resources. Several tungsten mining projects have been developed or explored. Its relatively stable geological conditions, mining policies, and infrastructure make it one of the countries with the best tungsten resource distribution. - Zimbabwe

Zimbabwe has identified numerous tungsten deposits and mineralizations with substantial reserves. While the country has many and widely distributed mining areas, it may face challenges in infrastructure, power, and financing. - Uganda/Burundi, etc.,

Although these countries have slightly smaller or less mature tungsten resources than the two countries mentioned above, they possess potential within tungsten, tin, tantalum, and other associated element mineral belts. They are worth considering for early-stage exploration or small- to medium-sized mining projects.

Key Deposits and Mineralization Types

Country | Deposit Type | Key Mining Areas | Ore Characteristics |

DR Congo | Hydrothermal quartz veins | Kisengo Deposit | High-grade (WO₃ 1.2-2.5%), associated with cassiterite |

Rwanda | Placer + Primary ore | Gatumba Deposit | Fine-grained (0.1-0.5mm), high clay content |

Nigeria | Pegmatite-type | Egbe Deposit | Low-grade (WO₃ 0.3-0.8%), uneven grain size |

Beneficiation Challenges in Africa

- High ore dilution: Artisanal mining introduces waste rock, typically reducing feed grades to <1% WO₃;

- Dominance of fine particles(e.g., 40% -0.074mm fraction in Rwandan placer ore);

- Infrastructure constraints: Unstable electricity supply necessitates reliance on non-powered/low-energy equipment (e.g., spiral concentrators).

Wolframite Gravity Separation Processes

The following describes two typical wolframite gravity separation processes: Process 1 and Process 2. Each process is explained from crushing and beneficiation equipment to concentrate output, and the applicable conditions and key technical points are also indicated.

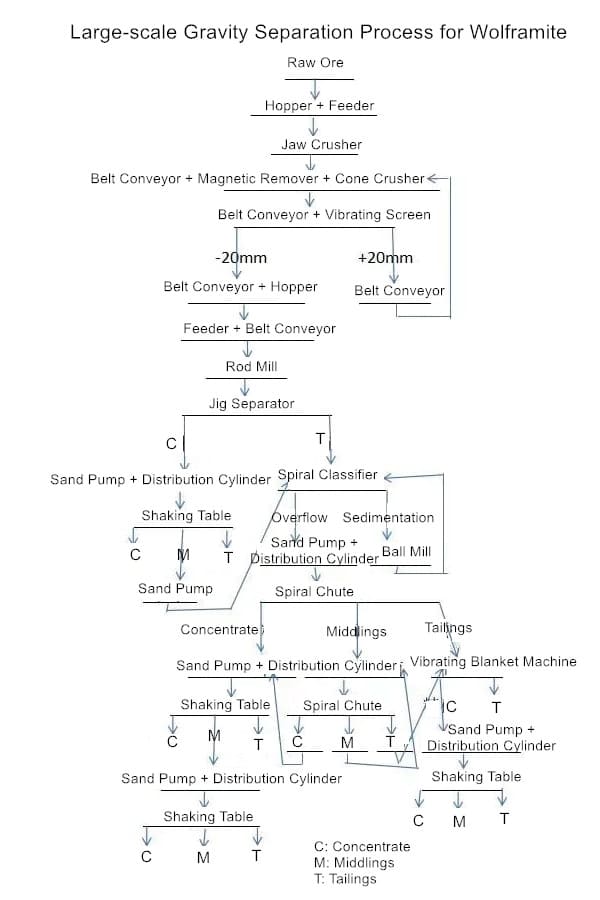

Process 1: Large-scale Gravity Concentrator Process

Note: Refer to “maximum particle size approximately 600mm, processing capacity approximately 50t/h”

In this process:

- Raw ore → Silo + Feeder → Jaw crusher → Iron removal + Cone crusher

- The output is divided into two paths: “-20mm” and “+20mm”: -20mm enters the rod mill, then proceeds to the jig for roughing.

- After the jig, the material is pumped by a sand pump and a distributor into the spiral classifier. The tailings or middlings from the spiral classifier then enter a spiral sluice or shaking table for fine cleaning.

- Concentrate, middlings from gravity separation, and tailings are output separately.

Technical advantages: Suitable for concentrators with large raw ore particle sizes, difficult ore liberation, or large-scale operations; employs multi-stage gravity equipment in series to improve recovery rates.

Precautions: The rod mill indicates that fine crushing/semi-grinding is still required, resulting in higher energy consumption, equipment investment, and maintenance costs; the process is also more complex, requiring high-level on-site management.

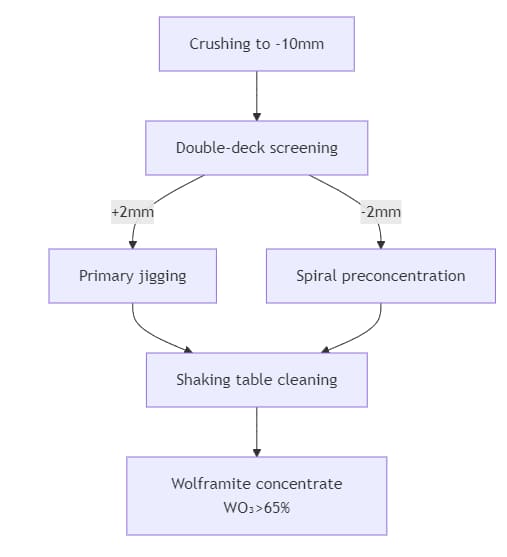

Process 2: Simplified Gravity Process

This simplified gravity process is suitable for coarse-grained, well-liberated Wolframite ores.

Process steps are as follows:

Raw ore → Vibrating feeder → Washing + screening (e.g., removing large pieces + 5mm coarse material) → Cone crusher or sand mill → Spiral washer (desliming/screening) → Jig → Shaking table → Output concentrate/mid-ore/tailings.

Technical advantages: Relatively simple structure, fewer equipment, lower investment, shorter construction period, especially suitable for beneficiation plants in remote areas or areas without power grids.

Applicable conditions: Ore with moderate particle size, good liberation, low clay/silt content, and coarse-grained materials can be fully recovered by gravity.

Limitations: If ball milling is not performed, liberation is insufficient, there are severe inclusions, or the clay content is high, the recovery rate of this process may be insufficient.

Technology Selection Recommendations

If the ore is large, difficult to liberate, and the scale is large: Process 1 is recommended, equipped with a combination of crushing → grinding → jigging → spiral → shaking table to improve recovery efficiency.

If the ore is well liberated, has a moderate size, and site conditions are limited (e.g., energy, transportation, capital): Process 2 is recommended as a priority, starting with a small-scale operation for lower costs.

Before designing the concentrator, ore screening analysis, mineral liberation tests, and clay content testing must be conducted to determine whether ball milling or flotation can be skipped.

In areas far from the power grid and reliant on diesel generators, simplified processes, low energy consumption, and simple equipment maintenance are particularly important. Gravity lines offer significant advantages: low energy consumption, simple structure, and controllable operating costs.

Regardless of the process, tailings treatment, water recycling systems, safety and environmental protection, and operation and maintenance must be planned simultaneously.

Typical Gravity Separation for African Wolframite

Kisengo Mine (DR Congo): Jig-Shaking Table Hybrid Circuit

Target Ore: Medium-coarse wolframite (0.5-5mm) with cassiterite. Core Flowsheet:

Key Techniques:

- Jig recovery ~75%, producing 50–55% WO₃ concentrate;

- Spirals pre-reject tailings to reduce shaking table load;

- Shaking table separates wolframite from cassiterite (optimum stroke: 8–10mm).

Gatumba Mine (Rwanda): Centrifugal Concentrator-Shaking Table Fine Separation

Target Ore: Fine-grained placer (-0.2mm dominant)

Innovations:

- Hydrocyclone desliming: Removes -0.038mm slimes (25% mass);

- Falcon centrifugal concentrator: Recovers 10–100μm wolframite, achieving 15% higher recovery than shaking tables;

- Enhanced classification: High-frequency screens control feed size.

Conclusion

Africa’s wolframite resources present significant opportunities amid rising global tungsten demand, reflected in soaring APT contract prices. While the continent hosts substantial deposits—particularly in DR Congo, Rwanda, and Nigeria—challenges persist, including fine-grained ores, infrastructural limitations, and technological gaps. Gravity separation remains the cornerstone of African wolframite processing due to its cost-effectiveness and adaptability to local conditions. Innovations like centrifugal concentrators and modular plants are addressing historical inefficiencies, yet sustainable development hinges on overcoming power shortages, skill deficits, and fine-particle recovery hurdles. Strategic international partnerships and AI-driven optimizations could unlock Africa’s potential as a key tungsten supplier in the energy transition era.