Double-roll crushers are essential equipment in mining and construction. They efficiently crush materials like limestone and granite, meeting the demands of high-speed railways and sand production. But how well do you understand their functions and benefits?

Double-roll crushers consist of two parallel rolls rotating inward to crush materials fed between them. They are ideal for medium to hard materials like coal, limestone, and ores. Their advantages include uniform sizing, low dust production, and high crushing efficiency. These crushers are widely used in mining, construction, and aggregate industries.

Still unsure about how double-roll crushers can meet your needs? Let’s break down their applications, types, and selection criteria for better clarity.

Table of Contents

What Is the Need for Roll Crushers?

Crushing raw materials efficiently is critical in mining and construction. The roll crushers have been supplanted mainly by cone crushers in most installations. They’re likewise helpful in treating Brittle, viscous, frozen, and less harsh feeds, including limestone, fuel, chalk, gypsum, phosphate, and soft iron ores that aren’t too rough. In crushing, the roll crushers simplify the process while ensuring durability. Why are they indispensable?

Roll crushers break down materials efficiently by compressing them between two rotating rolls. They reduce oversized chunks into manageable sizes without excessive fines. Their design ensures reliable performance, low maintenance, and energy efficiency compared to other crushing methods.

Roll crushers address specific challenges in material processing:

Types of Crushing Needs Roll Crushers Fulfill:

| Application | Why Roll Crushers? |

| Reducing oversized chunks | Gentle compression avoids dust buildup |

| Consistent particle sizing | Adjustable gap ensures uniform output |

| Handling sticky or damp ores | Anti-clogging design prevents material buildup |

Roll crushers excel in tasks that require precision crushing without generating excess fines. They outperform jaw crushers in producing uniform grains for construction aggregates or coal preparation.

What Are the Applications of a Double-Roll Crusher?

From mining to recycling, double-roll crushers deliver versatile crushing solutions. Where exactly are they used?

Double-roll crushers process materials such as coal, limestone, clay, and ores in industries including mining, cement, and construction. Their ability to handle abrasive or sticky substances makes them ideal for aggregate production and mineral processing.

Industries Where Double-Roll Crushers Are Crucial:

1. Mining – Crushes coal, iron ore, and other minerals for processing.

2. Cement Production – Produces finely crushed raw materials for clinker.

3. Construction – Creates uniform aggregate sizes for roads and concrete.

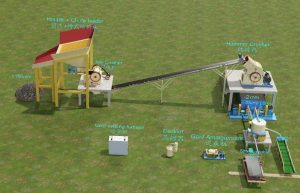

4. Sand Plants – Processes pebbles and granite into construction sand. These crushers adapt seamlessly to different settings due to their robust structure and controllable output sizing.

What Are the Key Advantages of a Double-Roll Crusher?

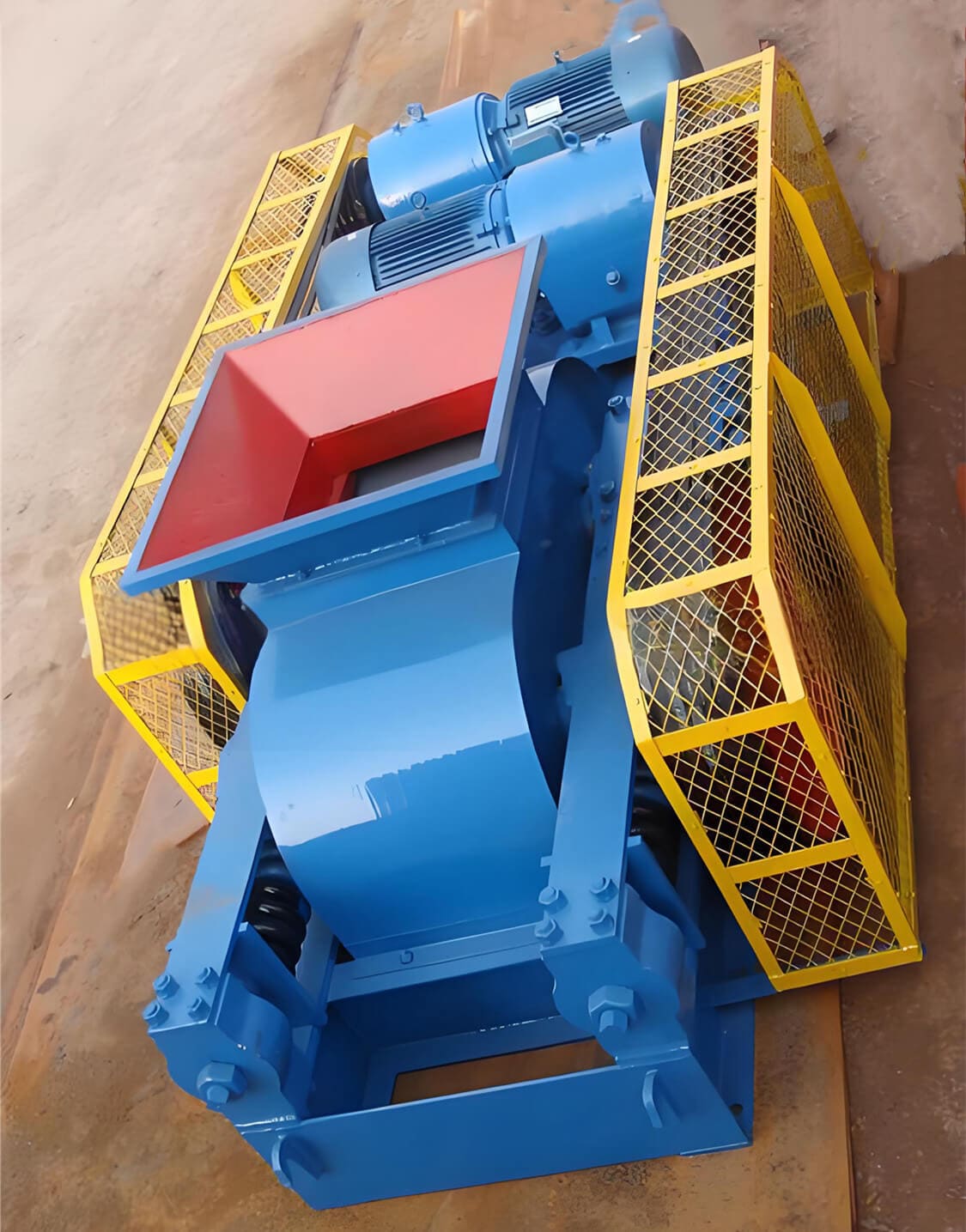

The unique design of a double-roll crusher provides several key benefits over other crushing equipment, making it ideal for handling brittle and medium-hard materials. Below are the primary advantages of double-roll crushers:

1. Low noise, reliable performance

The double-roll crusher technology boasts robust production capabilities and stable, dependable performance. It reduces noise pollution, delivering environmental benefits.

2. High production efficiency, large processing capacity

The crushed product exhibits a cubic shape with low needle and flake content and no internal cracks. The fine output particle size enhances production quality and efficiency.

3. Extended wear part lifespan with minimal loss

Roll shells exhibit extended wear cycles. Wear parts utilize domestically advanced high-strength, wear-resistant materials capable of crushing high-hardness materials. Minimal loss and extended service life deliver substantial economic benefits to customers.

Double-roll crushers are valuable assets in mineral processing and aggregate industries due to their adjustable sizing, energy efficiency, durability, and ability to handle challenging materials. Their simple yet robust design makes them an economically favorable choice for operators seeking reliable size reduction with minimal downtime.

What Types of Double-roll Crushers Are Available?

Double-roll crushers can be classified into several types based on their roll surface design, drive mechanism, application specialization, and adjustability. Here are the main types:

1. By Roll Surface Design: Smooth Roll Crusher, Toothed/Corrugated Roll Crusher, Segmented Roll Crusher.

Smooth Roll Crushers feature flat or lightly textured roll surfaces, making them ideal for fine crushing of soft to medium-hard materials such as coal, limestone, and phosphate. They produce uniform-sized particles with minimal fines. Toothed or Corrugated Roll Crushers, on the other hand, have rolls with teeth, grooves, or corrugations that provide better grip, making them suitable for coarser crushing of hard or abrasive materials like iron ore, shale, and slag. These designs reduce slippage and enhance crushing efficiency. For highly abrasive materials such as certain ores or recycled concrete, Segmented Roll Crushers are preferred. They feature replaceable wear segments (e.g., tungsten carbide inserts), which simplify maintenance by allowing worn segments to be replaced individually rather than requiring full roll replacement.

2. By Drive Mechanism: Dual Motor Drive, Single Motor Drive, Hydraulic Drive.

Double-roll crushers can operate under different drive configurations. Dual Motor Drive crushers use separate motors to power each roll independently, allowing precise speed control and reducing the risk of jamming. Meanwhile, Single Motor Drive crushers rely on one motor to drive both rolls via belts or chains, offering simplicity but less flexibility in roll speed adjustment. For heavy-duty applications requiring robust overload protection and pressure adjustments, Hydraulic Drive crushers are often employed, utilizing hydraulic systems to regulate roll operation efficiently.

3. By Application Specialization: Heavy-Duty Roll Crusher, Light-Duty Roll Crusher, Hybrid Roll Crusher.

Depending on industrial needs, roll crushers come in specialized designs. Heavy-Duty Roll Crushers are built with reinforced frames and wear-resistant rolls for demanding tasks like mining and quarrying, particularly primary crushing of iron ore. In contrast, Light-Duty Roll Crushers are compact machines suitable for smaller-scale operations, such as coal sampling or ceramic raw material preparation. Additionally, Hybrid Roll Crushers combine features of roll crushers with jaw or impact crushers to enhance versatility, such as roller mills integrating additional grinding mechanisms for finer outputs.

4. By Adjustability: Fixed Gap Roll Crusher, Adjustable Gap Roll Crusher

The gap between rolls determines the output size, leading to two main configurations. Fixed Gap Roll Crushers have preset roll spacing, making them efficient for consistent feed materials where uniformity is critical. Conversely, Adjustable Gap Roll Crushers allow operators to modify the spacing either hydraulically or mechanically, providing flexibility when processing materials requiring different particle sizes or when feed characteristics vary.

What Materials Can a Double-roll Crusher Process?

A double-roll crusher excels at processing brittle, friable materials of low-to-mid hardness. The following are the materials that can commonly be processes.

Category | Examples | Notes |

Coal & Coke | Bituminous coal, anthracite, petroleum coke | Ideal for primary/secondary crushing in coal preparation plants. |

Minerals | Limestone, gypsum, phosphate rock, salt | Handles soft to medium-hard rocks well. |

Ores | Iron ore, manganese ore, bauxite (laterite) | Used in mining for primary size reduction. |

Oil Shale | Kerogen-rich shale | Requires an adjustable roll gap for varying hardness. |

Clay & Shale | Kaolin, bentonite, ceramic clay | Avoid excessively sticky/wet material to prevent clogging. |

Aggregates | Sandstone, chalk, marl | Produces uniform particle sizes for construction. |

Double-roll crushers can conditionally process materials like dry, cooled metallurgical slag (while molten or wet slag may damage rolls), frozen materials (if pre-crushed or heated), and dry, non-fibrous biomass (wood chips, straw). However, they are unsuitable for extremely hard materials (granite, basalt >250 MPa), highly abrasive substances (quartz, silicon carbide), ductile materials (metals, rubber, plastics that wrap around rolls), sticky/wet substances (wet clay, tar, asphalt causing clogging), and fibrous materials (long plant fibers, ropes that entangle rolls).

How to Choose The Roller Crusher?

To choose a good double roll crusher, it’s recommended to visit the factory directly to inspect the equipment. JXSC has compiled four points to consider when purchasing, hoping to help you buy the right equipment.

1. Quality: Equipment quality is key. Buyers of double roll crushers are advised to thoroughly understand the equipment’s quality, such as whether its wearing parts are made of high-manganese chromium materials. Focus on quality rather than being tempted by low prices.

2. Crushing Ratio: The crushing ratio varies between manufacturers. Too coarse or too fine a ratio is not ideal. Bring some material for a test run before purchasing.

3. Energy Consumptio n:While considering economic benefits, energy consumption is also crucial. The energy consumption of a double roll crusher is mainly concentrated in the crushing chamber. Pay attention to the friction levels of various components. Choosing a double roll crusher with low energy consumption will ensure better economic efficiency.

4. Evaluation: Choose large manufacturers with strong operating capabilities, comprehensive after-sales service, reliable quality, and good reputations. After-sales service is also guaranteed.

Conclusion

Double-roll crushers are indispensable for processing materials like coal, limestone, and ores efficiently. Their adjustable crushing, low maintenance, and versatility make them ideal for mining, construction, and aggregates. Selecting the right type ensures optimal performance for your project needs.