In China’s lead-zinc ore resources, approximately 28% consist of ore deposits with dips exceeding 55° and moderate-to-thin thicknesses. Efficiently extracting such ore bodies has long been a major challenge in the mining industry. Traditional cut-and-fill methods incur high costs, while caving methods are constrained by geological conditions. The Shallow Hole Stope Mining Method, a classic open-stope approach, employs a temporary self-supporting ore pillar mechanism to maintain stope stability while significantly reducing extraction costs.

What is the Shallow Hole Ore-Stopping Mining Method?

The shallow hole ore-stopping method is an underground mining technique used primarily for thin or extremely thin ore bodies (typically less than 4–5 meters thick) with a steep dip (>60°).

Key Features of the Method

Layout Design

- The ore body is divided into mine rooms separated by pillars.

- Raise (quasi patio) and horizontal connecting driftsare developed within these pillars to link with the stope.

Mining Process

- Ore is extracted in horizontal slices.

- Drilling is done perpendicularor at a 45°–90° angle to the blastholes.

- To reduce ore loss (especially in fracture-filled thin veins), shallow blastholesare used—typically no deeper than 5 times the mining width.

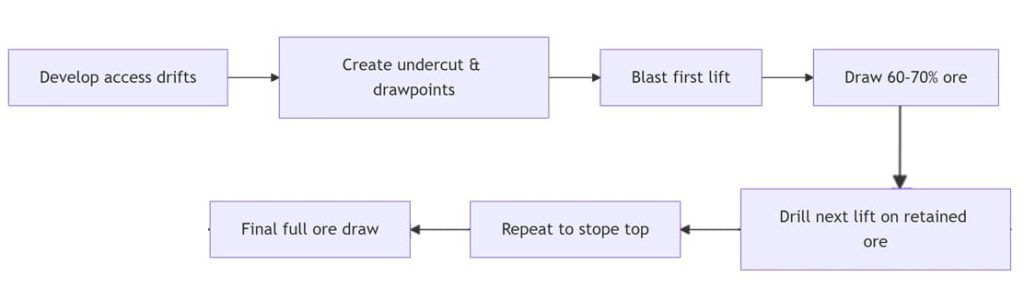

Workflow Example

Advantages

- Better ventilationcompared to other methods.

- Fewer disruptive factorsin the stope, enabling higher productivity.

Disadvantages

- High pillar ore loss: Since pillars occupy a significant portion of the ore body, recovery rates are low.

When Is It Used?

This method is suitable for narrow, steeply dipping veins, where conventional bulk mining techniques cannot be efficiently applied.

Ideal Conditions for Lead-Zinc Deposits

Key Parameter | Optimal Range | Risks Beyond Range |

Ore Body Dip Angle | >55° (steeply dipping) | <45° may hinder ore flow |

Ore Stability (f-value) | f ≥ 8 (moderate-high strength) | Weak ore risks wall collapse |

Ore Body Thickness | 2-8m (thin to moderate) | Excessive thickness complicates management |

Harmful Element Content | Low sulfur & arsenic | High sulfur risks spontaneous combustion |

Lead-Zinc-Specific Considerations

- Cadmium/arsenic-rich zonesrequire isolated extraction to prevent pollution spread.

- Highly oxidized oredemands optimized blasting parameters to minimize fines generation.

Shallow Hole Stoping Method for Lead-Zinc Mine

Mining Process

When employing the shallow hole stoping method at a lead-zinc mine, the mining process follows a strict sequence and operational protocols.

Workings Layout

The first step is workings layout. Based on the ore body’s occurrence conditions, parameters such as the strike, length, and width of the working are determined. This lead-zinc mine’s working is oriented along the ore body’s strike. Dimensions like working length, width, and height are determined by comprehensively considering factors such as rock stability and ore body thickness to ensure mining safety and efficiency. For instance, in more stable sections of the ore body, the working length may be appropriately increased to enhance mining efficiency.

Drilling Operations

Subsequently, drilling operations are conducted to prepare for subsequent charging and blasting. Workers use shallow-hole drilling rigs to drill holes in the mine walls according to pre-designed blast hole parameters. Strict requirements govern the spacing, row spacing, depth, and angle of the drill holes. These parameters are determined based on factors such as ore hardness and the development of joints and fractures within the ore body. For instance, with harder ores, the spacing between drill holes is reduced to ensure effective blasting. In practice, workers must master the operation techniques of the rock drills to guarantee the quality of the drill holes, laying the foundation for subsequent blasting operations.

Charging and Blasting

Charging and blasting constitute a critical phase in the mining process. After drilling is complete, explosives are loaded into the boreholes according to the designed charge quantity and pattern before initiation. Explosive selection is determined by rock properties and blasting requirements, while strict adherence to blasting safety protocols ensures secure operations. Before blasting, a comprehensive inspection of the mining area is required to ensure personnel and equipment are evacuated to safe zones. Post-blasting, a certain volume of large rock fragments may be generated, potentially necessitating secondary crushing to meet ore discharge and transportation requirements.

Ventilation

Ventilation is critical for ensuring the safety and health of personnel working in mining areas. After blasting, large amounts of harmful gases and dust are generated within the mining area, necessitating prompt ventilation. In lead-zinc mines, fresh air flows enter through the stage haulage road, pass through the shaft and connecting road into the mining area, expelling harmful gases and dust from the mining area, and are discharged to the surface via the return air road. The ventilation system must maintain sufficient air volume and pressure to ensure effective airflow. Additionally, ventilation monitoring equipment is installed to continuously track air quality within the mining area, guaranteeing compliance with safety standards.

Local Ore Release

Local ore release occurs after each blast, typically discharging approximately one-third of the ore beneath the blast area. Ore is discharged through a chute, collected by ore cars positioned below, and transported out via the stage haulage road. During partial ore discharge, the discharge volume and speed must be carefully controlled to maintain a level ore face, creating favorable conditions for subsequent operations. Throughout the discharge process, close observation of the chute and haulage road is essential to prevent blockages and other issues.

Clearing Loose Rock

Clearing loose rock is also an essential step. After partial mining, loose ore may remain on the roof and side walls of the mining area. Tools are used to pry and remove this loose rock to prevent it from falling and causing injury. Simultaneously, the retained ore pile is leveled to provide a flat working surface for the next layer of drilling operations. At this lead-zinc mine, workers employ specialized tools for rock removal to ensure operational safety.

Mass Ore Release

Once the entire mining chamber is fully excavated, a mass ore release is conducted to discharge approximately two-thirds of the ore remaining within the chamber. During this process, uniform ore discharge must be maintained to prevent blockages in chutes or other equipment. A comprehensive inspection and maintenance of the entire ore discharge system is required at this stage to ensure its proper functioning. Upon completion of the mass ore release, mining operations in this chamber are essentially concluded.

Advantages and Challenges

Advantages

The shallow-hole mining method offers significant advantages when extracting steeply dipping thin and steeply thin ore bodies.

From a technical perspective, the process is relatively simple, easy to master, and operate, making it highly practical for mines with limited technical capabilities and equipment conditions. Workers can proficiently master the mining process after basic training, eliminating the need for complex techniques or high-end equipment, thereby lowering the technical barrier to mining.

Cost-wise, the shallow-hole mining method also offers distinct advantages. Since it does not require large, expensive mining equipment, equipment procurement and maintenance costs are lower. Additionally, the relatively simple mining structure and reduced development and cutting workloads lower construction costs. For instance, small-scale mines adopting this method can achieve efficient extraction within limited budgets, yielding significant cost savings for enterprises. Furthermore, during extraction, approximately one-third of the mined ore is discharged per cycle, with the remaining ore serving as a temporary working platform. This eliminates the need for dedicated platform construction, saving both costs and time.

Challenges

However, the shallow-hole stoping method also faces certain challenges.

Low mechanization is a prominent issue. In lead-zinc mines employing this method, many operations—such as drilling, charging explosives, and leveling the working face—still rely on manual labor. Workers endure high physical demands, and production efficiency struggles to improve significantly. Compared to highly mechanized mining methods, the shallow-hole stoping technique has relatively limited production capacity in mining areas, making it difficult to meet the demands of large-scale mines.

Safety risks are also significant. During mining operations, workers operate directly within exposed chambers, facing hazards such as roof collapses and falling rock. These risks are particularly heightened in areas with unstable rock and ore conditions. Inadequate ventilation systems may fail to promptly exhaust harmful gases and dust generated by blasting, posing health hazards to workers. Safety incidents like funnel blockages or sudden rock collapses can also occur during localized or large-scale ore discharge operations.

Conclusion: Optimal Solution for Small-to-Medium Lead-Zinc Mines

In the mining sector, selecting the appropriate mining method is crucial for achieving efficient and safe extraction. As a classic and widely applied technique, the shallow-hole stoping method has held significant importance in China’s mining history. It is suitable for mining ore bodies under specific conditions, enabling efficient extraction of underground ore through thoughtful design and operation. With its low investment and high flexibility, the shallow-hole stoping method is an ideal choice for steeply dipping thin to medium-thick lead-zinc ore bodies. In the future, with the maturation of intelligent blasting control and digital twin monitoring technologies, this method is expected to achieve breakthroughs in resource recovery rates (target 90%+) and operational safety. For the lead-zinc processing, you can ask the mineral ore solution supplier, such as JXSC.