In the rugged terrains of Mexico, where quartz-laden gold ores hold hidden wealth beneath their hardened surfaces, efficient mineral processing isn’t just a preference—it’s a necessity. For small-scale miners and emerging operations, balancing cost, recovery, and scalability is critical. That’s why our recent 5-ton-per-hour (TPH) rock gold processing plant, custom-engineered for a Mexican client, exemplifies smart, gravity-based gold recovery.

Quartz-hosted gold deposits pose unique challenges—liberating fine gold requires precision crushing while maximizing recovery demands optimized concentration. Many traditional setups default to ball mills for grinding, but our tailored solution proves that hammer crushers, centrifugal concentrators, and shaking tables can achieve 85–90% recovery without unnecessary complexity or high costs.

In this case study, we’ll explore how JXSC’s compact processing line transforms raw 200mm quartz ore into pure gold concentrate—step by step, machine by machine—and why this gravity-driven approach is ideal for Mexico’s resourceful miners.

5TPH Rock Stone Gold Processing Plant In Mexico

Client’s Mine Situation And Requirements

This 5tph rock stone gold processing plant is designed for a Mexican client.

Customer’s Rock Stone Gold Project Information:

- Rock stone mine location: Mexico

- Raw ore condition: Hard Quartz stone, most stone sizes are around 200mm, crushing at 2mm can release the inside gold from the rock.

- Customer’s main requirements: 5tph as a small start, higher recovery rate.

Processing Flowsheet

From Ore to Gold: The Processing Flow Breakdown

Our Mexico client’s ore was classic hard-rock gold—quartz-dominated, with gold trapped inside particles up to 200mm in size. Testing confirmed that crushing to ≤2mm liberated the gold efficiently, eliminating the need for finer grinding.

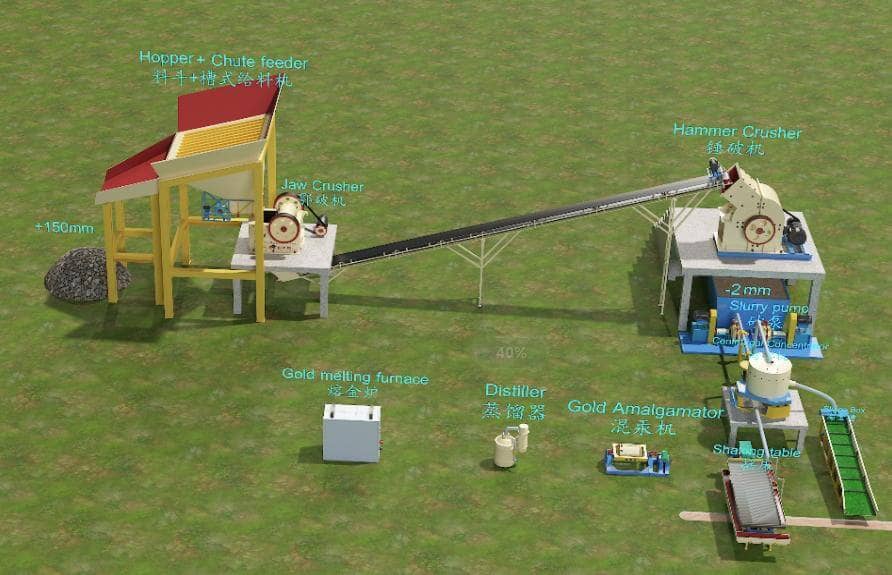

The solution is designed based on the client’s mining conditions and requirements. It is configured with a hopper, and under the hopper connects with one chute feeder to feed materials into the jaw crusher more evenly. Here’s how the plant delivers:

1. The jaw crusher crushes the big stone size, less than around 60mm, and the output will be transported to the hammer crusher via the belt conveyor.

2. The first crushed material goes to the hammer crusher. Hammer crusher grinds materials to be fine, less than 2mm.

3. The 2mm material goes to the gold centrifugal concentrator for enriching and concentrating gold first.

4. Tailings of the centrifugal concentrator go to the sluice box for recovering more gold.

5. Concentrates of centrifugal concentrator and sluice box are sent to the shaking table for concentrating gold.

The Main Machines include the following:

| Item | Model | QTY(set) |

| Chute Feeder | 600*500 | 1 |

| Jaw Crusher | PE250*400 | 1 |

| Belt Conveyor | B500*20 | 1 |

| Hammer Crusher | PC600*400 | 1 |

| Gold Centrifugal Concentrator | STLB60 | 1 |

| Sluice Box | 1*4m | 1 |

| Shaking Table | 6S-4500 | 1 |

| Water Pump | IS60 | 1 |

| Water Pump | IS80 | 1 |

Customer Questions & Our Answers

① How to make the feeding hopper?

The drawing of the hopper will be offered after the order, the customer can weld the hopper in the mine site base on the drawing by steel plates.

② What is the particle size requirement for the feed ore?

Base on raw feeding capacity 5tons per hour, the particle size should meet the maximum feeding size of the feeder and jaw crusher that should below 200mm.

③ Why do you use a hammer crusher instead of a ball mill?

Because the ball mill is more suitable for fine gold recovery, if crush at 2mm can release the inside gold from rock efficient, use the hammer crusher more suitable. Their has screen mesh under the hammers to make sure the output size to 0-2mm.

④ What’s the function of the centrifugal concentrator?

The centrifugal concentrator is for pre-concentrating the gold from the 0-2mm slurry of the hammer crusher

⑤ What’s the function of the shaking table?

The shaking table for re-concentrating the gold concentrate from the centrifugal concentrator to reach a higher purity.

⑥ What gold recovery rate can be achieved?

The gravity recovery rate can reach 85–90%, final result will depend on the ore condition.

⑦ What’s the water consumption of the whole line machines?

The total water consumption will need approx 70m3 per hour, mainly the back wash water for the centrifgual concentrator and feeding water for hammer crusher and shaking table.

⑧ Can you provide the civil foundation drawing of the complete machines line?Once we receive your deposit payment, our engineer will design the detailed plant layout drawing, foundation drawing for you, and also the each main machine’s drawing & machine operation manual. All the technical support will be provided to assist with the installation.

Manufacturing, Delivery & Installation

Why This Solution Works for Small-Scale Miners?

Unlike large-scale cyanide leaching setups, this plant is affordable, easy to install, and scalable:

♦ Higher Recovery (85–90%): Beats traditional sluices or mercury amalgamation.

♦ Lower Energy Use: Hammer crushers outclass ball mills for mid-range grinding.

♦ Minimal Footprint: Compact design suits rugged or space-constrained sites.

Our client’s questions—from hopper fabrication to water needs—reflect practical concerns we’ve addressed across Latin America. Post-order, JXSC provides foundation drawings, operation manuals, and remote support, ensuring smooth commissioning.

Final Thoughts: The Smart Choice for Mexico’s Gold Future

For small miners in Mexico, investing in the right processing equipment isn’t just about output—it’s about sustainability, profitability, and adaptability. This 5TPH plant proves that advanced gravity separation doesn’t require massive infrastructure or prohibitive costs. Whether scaling up later or navigating water scarcity, the right design—such as this centrifugal and shaking table combo—can make all the difference.

As Mexico’s mining sector grows, JXSC remains committed to lean, high-recovery solutions tailored to local challenges. If quartz gold is your hurdle, perhaps this plant is your leap forward.

Got a similar project? Contact our engineers for a customized flowsheet—because gold recovery should never be one-size-fits-all.