Material: Alluvial gold ore

Max Feed Size:50mm

Capacity: 250tph

Client’s Mine Situation: The customer is processing alluvial gold with sticky clay and large waste stones, with gold concentrate mostly 0-6mm, and also has large nuggets below 12mm.

Process Description

JXSC has provided a complete set of processing plant machines for a Ghana customer: a 250tph alluvial clay gold Processing Plant. The client has their own engineering team to set up this plant, so there is no need for our engineer’s site service. While we offer the detailed layout design with base construction drawings, accordingly.

Client Background and Requirements

The Ghanaian client operates in an area rich with alluvial gold deposits characterized by sticky clay and significant waste stone content. Their target gold concentrate size primarily ranges from 0-6mm, with occasional larger nuggets up to 12mm. With their own engineering team available for installation, the client required a complete equipment solution with detailed layout design and foundation specifications, but no on-site installation service.

Our Process Design & Solution

The process is as follows

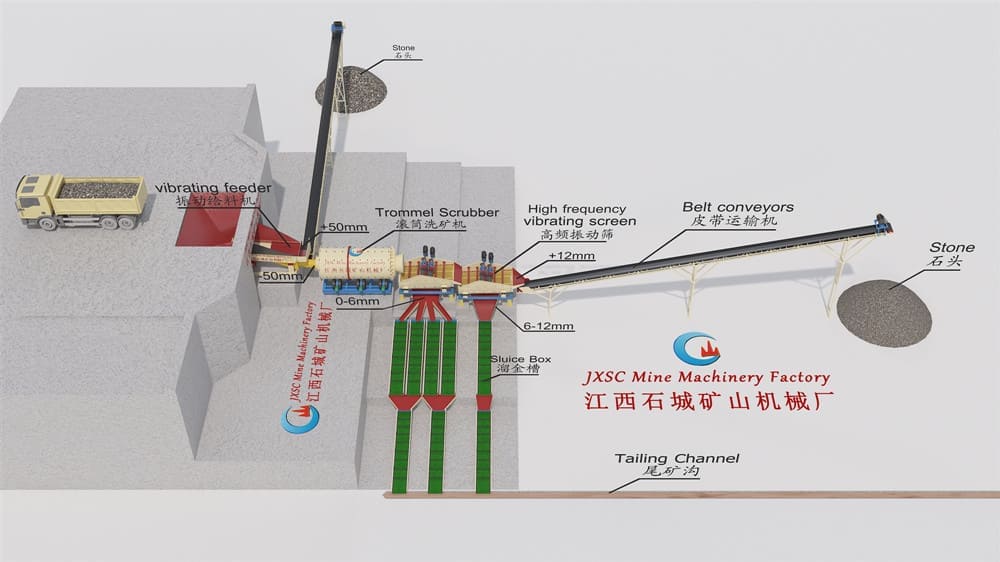

The 250tph alluvial gold process plant is configured with a hopper, vibrating feeder DN4520 with a gap of 50mm grizzly bar, JXSC-2400 trommel scrubber, two sets of high-frequency vibration screens(JXSC-2445 & JXSC-2045), 8 sets of sluice boxes, and two sets of belt conveyors.

Process Description

1. The truck unloads the ore into the hopper, the stone enters the vibrating feeder from the lower part of the hopper; the +50mm scrap will be separated by the vibrating feeder grizzly bar and transferred by a conveyor to a waste pile.

2. The vibrating feeder feeds the 0-50mm ores to the trommel scrubber to wash. They are connected by a trough.

3. The 0-50mm washed materials from the trommel scrubber will be sent to the first vibration screen with a 6mm mesh.

4. The material 0-6mm will pass through the mesh and flow to the 8 sets of gold sluice boxes. And materials 6-50mm will flow through the height difference to the next vibrating screen.

5. The materials 6-12mm will pass through the mesh and flow to the fifth gold sluice box. The 12-50mm scrap will be transferred by a conveyor to another waste pile.

6. The tails of the five gold sluice boxes will flow to another 3 sets of sluice boxes for further recovery.

7. Through this setup, you can get most of the gold particles. Follow-up can be equipped with a gold shaking table and other equipment for further selection. You can get other sizes of gold nuggets by changing the mesh sizes of the vibration screen.

The Main Machines & Accessories include the following:

| Product Name | Model No. | Quantity (Set) |

| Vibration Feeder | 4500*2000mm | 1 |

| Drum Scrubber Washer | JXSC-2400 | 1 |

| High Frequency Vibration Screen | JXSC-2445 | 1 |

| High Frequency Vibration Screen | JXSC-2045 | 1 |

| Belt Conveyor | 1200x14m | 1 |

| Belt Conveyor | 800x15m | 1 |

| Sluice Box | 1x6m | 8 |

| Double Suction Water Pump | 14SH-9 | 1 |

| High-Pressure Water Gun | 4inch | 2 |

| Gold Smelting Furnace | 15A | 1 |

Customer Questions & Our Answers

1. What’s the difference between the trommel scrubber and the trommel screen?

The trommel scrubber is used for washing the raw materials with much sticky clay, and the trommel screen is used for washing the raw materials with normal sand and soil.

2. What is the particle size requirement for the feed ore?

The maximum feeding size of the vibrating feeder is 500mm, and the vibrating feeder will be equipped with a 50mm grizzly bar(the grizzly bar gap can be customized) to remove the +50mm big waste stones before feeding to the trommel scrubber.

3. Why the trommel scrubber without the screen part?

Due to the big capacity of 250 tons per hour, the screen efficiency of the trommel scrubber will not be good, so we add the high-frequency vibration screen for the sieving work, and the trommel scrubber will just do the washing function. This combination will make the washing and sieving most efficient.

4. What’s the water consumption of the whole line of machines?

The total water consumption will need approximately 750 m3 per hour, mainly the feeding water for the trommel scrubber.

5. What’s the function of the high-pressure water gun?

The high-pressure water gun is for washing the raw materials before feeding them to the vibrating feeder, so that the materials will not stick together too much. It can also do pre-washing to make the washing work easier for the trommel scrubber.

6. Can you provide the civil foundation drawing of the complete machine line?

Once we receive your deposit payment, our engineer will design the detailed plant layout drawing, foundation drawing for you, and also each main machine’s drawing & machine operation manual. All the technical support will be provided to assist with the installation.