In the heart of Tanzania’s mining region, a comprehensive gold processing solution has been engineered to meet the specific challenges faced by small to medium-scale mining operations. This 2 TPH rock gold processing plant represents the perfect balance between efficiency, reliability, and operational simplicity – essential qualities for mining operations in regions with infrastructure limitations. Designed to handle rock gold ore with particle dissociation size of 0-1mm, this plant delivers professional-grade gold recovery in a compact, scalable package that adapts perfectly to the African mining context.

2TPH Rock Gold Processing Plant in Tanzania

Overview

Client’s Mine Situation

- Raw Ore: rock gold

- Feeding Size:0-200mm

- Gold Dissociation Particle Size:0-1mm

- Mine Site Location: Tanzania

Customer Requirements

- 2tph as the start, need 2 stage crushers, 1 ball mill, gravity separation equipment, pumps, and a gold smelting furnace. They required a reliable and easy-to-operate gold processing solution.

- Need gold ore processing plant equipment suitable for very fine gold particles.

- No need tailings water recycling system.

- Required a reliable and easy-to-operate gold processing solution with high gold recovery +80%.

Our Service for this project includes

- Design a whole plant flowchart

- Provide plant layout and foundation drawing

- Provide a complete set of processing plant equipments

- Shipping all machines to Dar es Salaam, Tanzania

- Provide technical support & installation instructions

Our Design & Solution

Processing Flowsheet Design

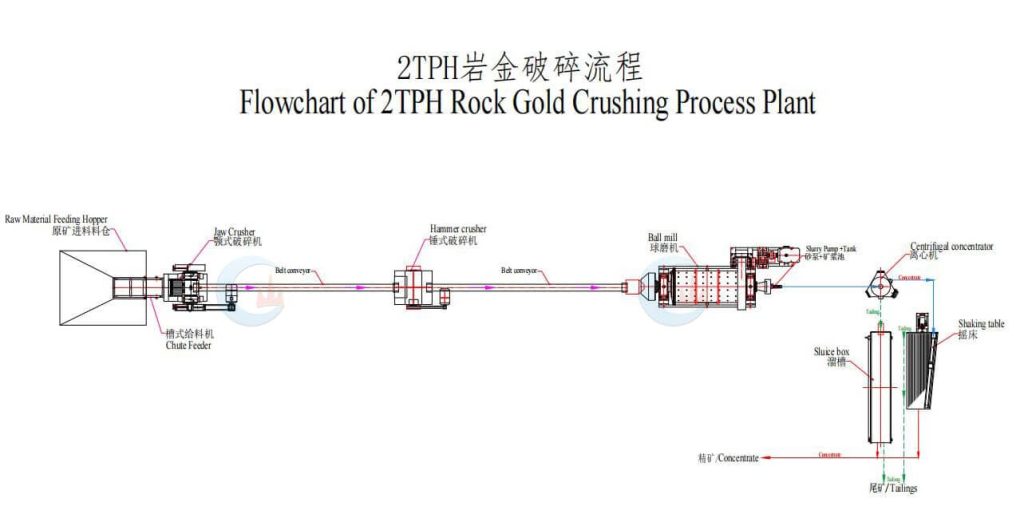

The designed flowsheet represents a complete 2TPH rock gold processing plant integrating crushing, milling, and multiple stages of gold recovery equipment.

Flowchart Explanation

This setup is a complete 2TPH rock gold processing plant, including chute feeder, jaw crusher, hammer crusher, ball mill, centrifugal concentrator, sluice box, shaking table, gold smelting furnace, and belt conveyors. This is a complete system from feeding rock ore to get the final product: gold concentrates.

- Loader or excavator feeds rock ore to the raw material hopper, then through the chute feeder smoothly feeds into the jaw crusher.

- Jaw crusher is primarily crushing big rocks to a medium size of 40mm below, its output goes to the hammer crusher by belt conveyor.

- Hammer crusher is a secondary crusher for crushing medium stones to a small size below 10mm, its output goes to the ball mill directly, by belt conveyor.

- The ball mill is for grinding fine ore from 0-10mm to a very fine powder size below 100 microns, so that the gold concentrate can be released completely from rocks.

- The output of the ball mill goes to the centrifugal concentrator by a slurry pump, for the first step of gold separation.

- The concentrates from the gold centrifugal concentrator will go to the shaking table for fine gold separation and upgrade the recovery rate.

- The tailings from the gold centrifugal concentrator will go to the sluice box for catching gold in case some gold flows away.

- Finally, all gold concentrates are sent to a gold smelting furnace for purification, so that customers can get pure gold bars.

The Main Machines include the following:

| Item | Model | QTY(set) | |

| Chute Feeder | 600*500 | 1 | |

| Jaw Crusher | PE200*300 | 1 | |

| Hammer Crusher | PC400*300 | 1 | |

| Ball Mill | MQZ0930 | 1 | |

| Steel Balls | / | 3 tons | |

| Gold Centrifugal Concentrator | 600 | 1 | |

| Shaking Table | 2100*1050mm | 1 | |

| Sluice Box | 4m*1m | 1 | |

| Gold Smelting Furnace | 15A | 1 | |

| Slurry Pump | 2/1.5 inch | 1 | |

| Water Pump | IS50 | 1 | |

| Belt conveyor | DT75-500*10m | 1 | |

| Diesel Generator | 80kw | 1 | |

Customer Questions & Factory Answers

Question: Many small mines in Africa have unstable power supplies, and some only rely on diesel generators. Is the power consumption of this 2 tph (tons per hour) system high? Can it be powered by a diesel generator?

Answer: Absolutely! This system is a low-power customized design. All equipment has been adapted for African power conditions, with a total installed power of only 60-70 kW. A single 100 kW diesel generator can power the entire production line at full load. Even with fluctuating power in African mines, the equipment has low-voltage protection devices to prevent motor burnout due to unstable voltage.

Furthermore, the hammer crusher and ball mill can be designed with variable frequency speed control, allowing for speed adjustment based on the generator’s power supply. This completely solves the problems of “unstable power, power shortages, and reliance on diesel generators” in African mines, eliminating the need for additional power supply equipment and reducing initial investment.

Question: This system processes low-grade gold ore (0.5-2 g/t). What is the overall gold recovery rate? How much higher is it than the recovery rate of simple gravity separation equipment used locally (such as only using shaking tables)?

Answer: For low-grade gold ore of 0.5-2 g/t, this system can achieve an overall gold recovery rate of 85%-90%, which is 20%-30% higher than simple gravity separation equipment using only shaking tables!

The core reason is that it addresses the “fine gold loss” problem of local equipment: with only shaking tables, fine gold particles of 0.01-0.074 mm are lost with the slurry.

However, the centrifuge in this system is a dedicated enrichment device for fine gold particles, which can efficiently recover this lost gold.

Combined with shaking tables for concentrating coarse gold particles, it achieves “fine particle + coarse particle” recovery across all particle sizes. Even with ultra-low-grade gold ore of 0.5 g/t, it can still achieve a stable gold output, making even low-grade mines profitable.

Question: What is the state of the tailings after processing with this system? Is a tailings pond required? Does it meet the environmental requirements of African mines?

Answer: The tailings are in the form of dry-stacked fine sand, eliminating the need for a tailings pond. It meets the environmental requirements of African mines, which do not have strict wastewater discharge regulations.

The gravity separation process using a ball mill, centrifuge, and shaking table does not involve the addition of any chemical reagents. Water is only used for grinding and separation, and the tailings water can be recycled after sedimentation in a settling pond. The water recycling rate is over 90%, requiring only a small amount of fresh water replenishment, with no wastewater discharge. The processed tailings have a moisture content of only 15%-20%, appearing as loose fine sand. They can be directly stockpiled or used for backfilling mined-out areas, eliminating the need for a complex tailings pond, reducing subsequent environmental investment, and avoiding environmental penalties.

Question: How many containers are needed for the entire processing Plant?

Answer: one 40HQ container

Question: If the customer wants to expand our mine’s production capacity later, from 2 tph to 4-5 tph, can this equipment be upgraded and expanded? Or will the customer need to buy a whole new set of equipment?

Answer: It can be directly upgraded and expanded without needing to buy a whole new set of equipment, leaving room for future production capacity increases!

This solution’s equipment combination uses a modular design. To increase production to 4-5 tph later, you only need to add one ball mill and one centrifuge; the shaking table and crushing equipment do not need to be replaced.

The manufacturer can directly provide expansion parts and technical modifications, aligning with the investment pace of some mine owners who prefer to “start with small-scale trial production and then gradually expand capacity,” avoiding large upfront investments and reducing investment risks.

Question: After obtaining the gold concentrate, how do you smelt it into gold bars?

Answer: JXSC provides a complete set of equipment, including a small to medium-frequency gold smelting furnace (with crucible) in 1-50kg specifications.

It occupies a small area and can be placed in an open space next to the gravity separation line, or indoors, without requiring additional civil engineering work.

Question: How do you process gold concentrate from the initial selection stage to producing gold bars that can be directly traded? What are the specific steps involved?

Answer: The process revolves around “impurity removal – gold melting – casting – purification”, ensuring precise gold extraction without waste:

- Roasting for impurity removal: The gold concentrate is placed in a roasting furnace and roasted at a low temperature (600-800℃) for 1-2 hours to remove sulfur, arsenic, carbon, and moisture from the gold concentrate, preventing smoke and impurities from affecting gold purity during smelting.

- Smelting and slag removal: The roasted gold concentrate is added to a medium-frequency furnace crucible, and flux (borax + soda ash) is added in proportion. The medium-frequency furnace is powered/heated with diesel to approximately 1300℃, melting the gold concentrate into a liquid state. The flux will form slag with gangue and impurities, which floats on the surface and can be skimmed off. What remains is pure liquid gold.

- Casting gold ingots: The liquid gold, after the slag is removed, is poured into a special gold bar mold. After natural cooling, rough gold bars (ingots) are obtained;

Conclusion

The 2 TPH Rock Gold Processing Plant represents an optimal solution for Tanzania’s gold mining operations, delivering professional-grade recovery rates in a package that addresses the unique challenges of African mining environments. With its low power consumption, high recovery efficiency, and modular design allowing for future expansion, this plant enables mine owners to start with manageable investment while maintaining a path to increased production capacity. The comprehensive support package ensures smooth implementation and operation, making this an ideal choice for mining entrepreneurs looking to maximize returns while minimizing operational complexity in Tanzania’s gold-rich terrain.