In the heart of West Africa’s mineral-rich Guinea, our team has deployed a specialized hard rock gold processing plant that combines robust engineering with efficient recovery techniques. This 25-ton-per-hour processing solution was designed specifically for quartz gold ore, addressing the unique challenges faced by small to medium-scale mining operations.

This case study will walk you through every aspect of the project – from initial ore analysis and process selection to equipment specifications and final results. You’ll discover:

- The careful planning behind each processing stage

- Key equipment choices and why they were selected

- How we achieved 85-90% gravity recovery rates

- Answers to common customer questions about similar setups

25TPH Hard Rock Gold Processing Plant in Guinea

Project Overview

This project is located in Guinea. The client is a local mining company, focusing on small-scale hard rock gold mining. They required a reliable and easy-to-operate gold processing solution.

With the project parameters clearly defined, let’s examine the raw material characteristics that shaped our equipment selection and processing approach.

Raw Ore Information

The raw ore is hard rock quartz gold with a maximum feed size of 150 mm. The gold particles are mainly fine gold, and need to be ground to 0-2mm size, to liberate the gold inside the rocks.

These ore properties directly informed our processing capacity requirements – both for initial operations and future scalability.

Processing Capacity Requirement

The client required a processing capacity of 25 tons per hour, with the possibility to upgrade to 30TPH or 40TPH in the future.

With these throughput targets established, our engineering team developed a multi-stage processing solution that balances efficiency with operating simplicity.

Our Process Design & Solution

Process Flowchart

Process Description:

- The chute feeder smoothly feedsraw ore into the jaw crusher.

- A jaw crusher crushes big rocks to medium size.

- Fine crusher is a secondary crusher for crushing medium-sized stones to a small size.

- The hammer crusher is for grinding fine ore to 0-2mm, so that the gold concentrates can be released completely from rocks.

- The centrifugal gold concentrator is used for the first step of gold separation from waste sands.

- The shaking table is used for fine gold separation and upgrades the recovery rate.

- The tailings from the gold centrifugal concentrator will go to the sluice box for recovering gold from tailings.

- Finally, all gold concentrates will be sent to a gold smelting furnace for purification, so that customers can get pure gold bars.

Main Equipment List

- Chute Feeder

- Jaw Crusher

- Fine Jaw Crusher

- Hammer Crusher

- Centrifugal Gold Concentrator

- Shaking Table

- Sluice Box

- Belt conveyors

- Water Pumps & Slurry Pump & Diesel Generator & Control Panel

Naturally, customers have questions when investing in processing equipment. Here are the most common inquiries we received about this plant’s design.

Customer Questions & Our Answers

① What gold recovery rate can be achieved?

The gravity recovery rate can reach 85–90%, depending on the ore condition.

②Is the equipment complete, and does it include a motor?

Yes, our machines are complete with a motor.

③ Why not use a ball mill machine?

Ball mills can grind materials down to 1mm, and hammer crushers can crush materials to below 2mm. Tests on this customer’s ore showed that crushing it to 2mm allows for the recovery of the maximum amount of gold, so 2mm is more suitable for him. Grinding it too finely would actually negatively affect the recovery rate.

④ Can you provide the equipment drawings?

Once we receive your deposit payment, our engineer will design the detailed plant layout drawing, foundation drawing for you, and also each main machine’s drawing & machine operation manual.

All the technical support will be provided to assist with the installation.

⑤ Why use the gold centrifugal after the hammer crusher, does it not go to the shaking table directly?

The main function of the centrifuge is to initially concentrate the gold concentrate. Because a single shaking table only has a processing capacity of 1-2 tons per hour, and this customer has a relatively large processing volume, using shaking tables after washing would require many shaking tables to meet their processing needs. Therefore, we recommend using a centrifuge to initially concentrate the gold concentrate.

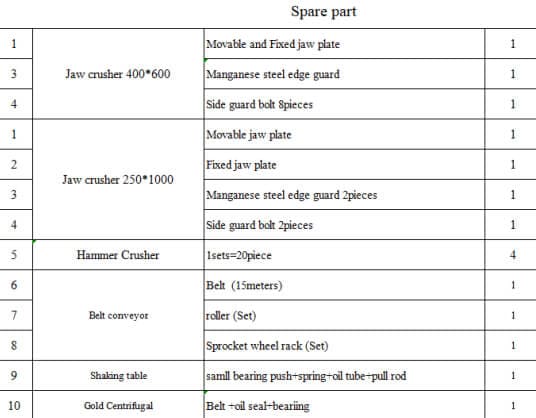

⑥Could you tell me the approximate replacement cycle for the wear parts?

Yes, we can provide an estimated replacement cycle for wear parts.

⑦ Why use two sets of hammer crushers, not use one hammer crusher?

Because the customer requires the material to be ground to less than 2mm, it’s difficult to guarantee this output requirement if we use a large-sized hammer crusher. Only a small-sized hammer crusher can ensure this output requirement. Based on the customer’s processing volume, two hammer crushers are needed to meet the customer’s output requirements.

The successful implementation of any mineral processing plant depends on careful manufacturing and smooth logistics. Here’s how we handled this project’s production and delivery phases.

Manufacturing, Delivery & Installation

This Guinea 25TPH Hard Rock Gold Processing Plant Applicable Clients

✔ Suitable for

- Small to medium-scale gold mining projects

- Hard rock or quartz gold ore

- Capacity from 20-25TPH

✖ Not suitable for

- Alluvial gold

- Very fine gold concentrate size plants

- Very large-scale industrial plants

Customer Feedback

The client is satisfied with the plant performance and gold recovery results. The system operates stably and meets the expectations. production target.

Why the Customer Chose JXSC?

- Customized processing solution.

- The company is ISO certificate approved, and the products are CE approved.

- Installation & technical support.

- A manufacturer of various mining machinery (including crushing equipment and mineral processing plants) with 40 years of experience.

Conclusion

This Guinea gold processing project demonstrates how customized solutions can unlock value even in small to medium-scale hard rock mining operations. By combining the right crushing technologies with optimized gravity separation methods, we helped our client achieve reliable gold recovery while planning for future expansion.

The success of this 25TPH plant showcases how modern mineral processing technology can be adapted to local mining conditions. Whether you’re operating in West Africa or other gold-rich regions, similar principles can be applied to develop efficient, cost-effective recovery systems.

Interested in exploring a customized solution for your ore body? Our team of mineral processing experts would be happy to assess your specific requirements and recommend an optimal setup.