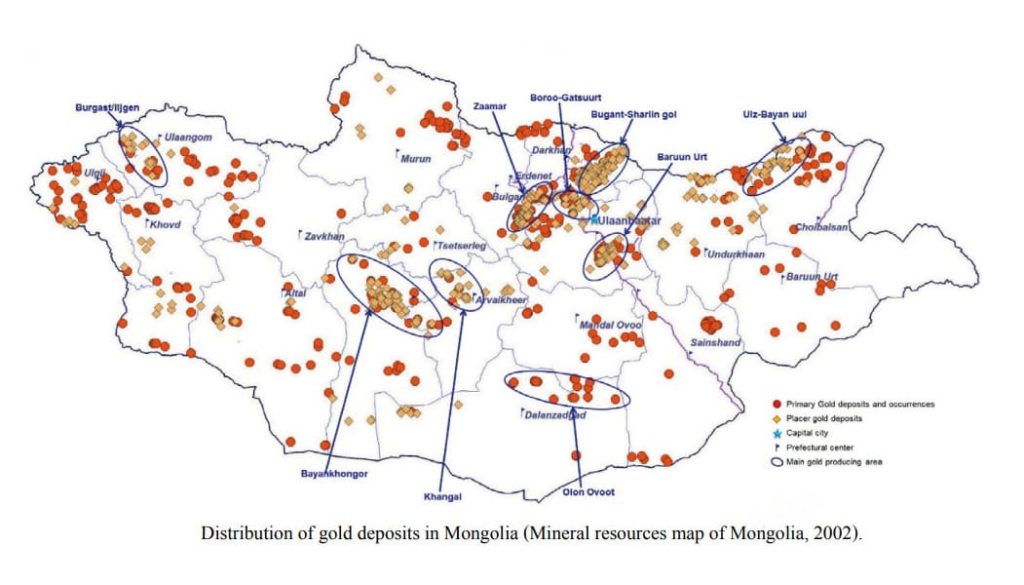

Mongolia possesses abundant gold resources distributed across various regions, with significant deposits located in the northern and western parts of the country. Gold mining plays a crucial role in Mongolia’s economy, contributing to both national revenue and local development. This article explores the distribution of gold resources in Mongolia and examines the commonly adopted mineral processing technologies for gold extraction. A comprehensive understanding of these aspects is essential for optimizing mining operations and ensuring sustainable resource utilization in Mongolia’s growing gold industry.

Gold Resources in Mongolia

Mongolia has rich gold resources, including placer gold deposits and primary deposits. These gold resources have been mined throughout history and now play an important role in the country’s mining activities and economic development. According to geological research reports, Mongolia has identified multiple mineralization belts and gold-bearing belts. Among them, seven mineralization belts are considered to have high gold potential, including North Khentii, Bayanhongor, Hangai, Jid, South Khentii, Ulziti, and Urgamal mineralization belts.

1. North KhentiiGold Belt(such as Boroo, Gatsuurt ,and other deposits)

Geographical location: Located in the north of Mongolia, covering Tov, Selenge, and Bulgan provinces, with a total length of about 400 kilometers and a width of 30-100 kilometers.

Geological characteristics: The belt is limited by two deep faults (Bayangol Fault in the north and Yoroo Fault in the south).

Ore deposit types: Magmatic hydrothermal gold deposits (such as Boroo, Gatsuurt); epithermal gold deposits (a few).

Main deposits: Including large deposits such as Narantolgoi, Sujigtei, Boroo, and Bumbat.

- Boroo Gold Mine: Medium-sized high-grade gold mine (average grade 2-4 g/t), with cumulative production exceeding 100 tons; Controlled by northeast faults, the ore body is located in quartz veins and alteration zones.

- Gatsuurt Gold Mine: Similar to Boroo, but with great potential for deep resources, with reserves of about 40 tons. Development is limited due to its location in a water source protection area.

Mineralization period: Late Jurassic-Early Cretaceous (about 150-120 Ma), related to the activities of the Mongolia-Okhotsk tectonic belt.

Mining status: Geological research is relatively sufficient, and most gold mining activities are currently concentrated here.

2. Bayanhongor Mineralization Belt

Geographical location: Located in the central and western part of Mongolia, in Bayanhongor Province, with a total length of 250 kilometers and a width of 60-90 kilometers.

Geological characteristics: Widely distributed volcanic-sedimentary rocks, sedimentary rocks, metamorphic rocks, and igneous rocks.

Main deposits: Concentrated in the Baidrag River Basin and Jargalant Mountains, mainly placer gold deposits.

Mining history: Mining began in 1939.

3. Jide Mineralization Belt

Geographic location: Located in the northernmost part of Mongolia, close to the Russian border.

Geological characteristics: The deposit is composed of volcanic rocks, sedimentary rocks, metamorphic rocks, and intrusive rocks, with gold mineralization associated with silver, copper, tungsten, molybdenum, and other minerals.

Mining status: Due to inconvenient transportation, there are few geological surveys, and the development potential has not been fully explored.

4. South Kent Mineralization Belt

Geographic location: Located in central Mongolia, with relatively favorable geographical and economic conditions.

Geological characteristics: Volcanic-sedimentary rocks and metamorphic rocks are widely distributed and are intruded by Paleozoic and Mesozoic granites.

Main deposits include Baligol, Tereli, Modot, and Janchivlan mining areas, where some placer gold mines have been in operation since 1902.

5. Uleji Mineralization Belt

Geographic location: Located in South Gobi Province and East Gobi Province.

Geological characteristics: Mainly sedimentary rocks and volcanic-sedimentary rocks, with limited water and fuel resources.

Development potential: Currently, there is little economic development, but it has the potential to discover primary gold mines.

6. Khangai Mineralization Belt

Geographic location: Located in the Khangai Mountains, covering Arhangai, Ovorhangai, and Zavhan provinces.

Main deposits: In recent years, large placer gold deposits have been discovered in the valleys of Khavtsgait, Olt, Zuun Sodot, and Baruun Sodot.

7. Urgamar Mineralization Belt

Geographic location: Located in western Mongolia.

Geological characteristics: Mainly volcanic rocks and intrusive rocks, gold mineralization is associated with copper, molybdenum, and other mineralizations.

Gold Mine Types

Gold mines in Mongolia are mainly divided into three economic types:

- Vine deposits:such as Narantolgoi, Bumbat, etc., with high gold grades (5.7-746 g/t).

- Mineralized belt deposits:such as Boroo deposits, which are related to hydrothermal alteration zones, with gold grades of 0.1-30 g/t.

- Placerous gold deposits:mainly distributed in the North Kent, Bayankhongor, and Khangai mineralization belts, such as Zaamar and Tolgoit placer gold deposits.

Gold Ore Beneficiation Processes in Mongolia

Mongolia boasts extensive gold resources with diverse ore types, and the beneficiation processes are selected based on ore characteristics (placer, primary, oxidized, or refractory) and gold occurrence (free-milling, sulfide-locked, or associated gold). Below is a detailed analysis of gold ore beneficiation processes in Mongolia.

1. Placer Gold Beneficiation Process

Major Mines: Tuul River, Zaamar, Ulaan Bulag

Key Features

- Roughing: Sluice boxes(fixed/vibrating) for small-scale operations (recovery: 60~80%); Jig concentrators (e.g., sawtooth wave jig) for medium-coarse gold (enrichment ratio up to 50:1).

- Cleaning: Shaking tables(e.g., 6-S table) for fine gold, upgrading to 500~1,000 g/t concentrates; Amalgamation (limited due to environmental concerns) for final concentrate purification (still used in some artisanal mines).

Typical Flow

Screening (removing >5 mm gravel) → Sluice/Jig roughing → Shaking table cleaning → Gold concentrate (direct smelting or mercury refining).

Case in Mongolia: Zaamar Goldfield uses gravity separation (jigging + shaking table) with a recovery rate of about 75% and an annual output of 2 to 3 tons of gold.

2. Hard Rock Gold Beneficiation Process

Major Mines: Boroo, Gatsuurt, Erdene Tolgoi

(1) Quartz Vein-Type (High-Grade Gold Ore)

Key Features

- Crushing & Grinding: Two-stage crushing (jaw + cone crusher) + ball milling (80% -200 mesh).

- Gravity separation: Knelson concentrator recovers free-milling coarse gold (>90% recovery, e.g., Boroo mine).

- Flotation: Sulfide-locked gold treated with xanthate collectors (e.g., ethyl xanthate), producing 30~100 g/t gold concentrates.

- Cyanide Leaching: Direct Carbon-in-Leach (CIL) process after grinding, achieving 85~95% gold recovery.

Typical Flow: Primary crushing → Secondary crushing → Ball milling → Knelson gravity separation → Flotation → CIL → Electrowinning.

Case in Mongolia: The Boroo gold mine adopts the combined process of “gravity separation + flotation + CIL”, with a total gold recovery rate of >90% and an annual output of 3 to 4 tons of gold.

(2) Porphyry Copper-Gold Ore

Major Mine: Oyu Tolgoi (South Gobi)

Key Features

- Bulk Copper-Gold Flotation: First recovers copper (chalcopyrite), then gold-bearing sulfides (e.g., arsenopyrite).

- Pressure Oxidation (POX) Pretreatment: Refractory gold ores are oxidized under high pressure (or bio-oxidation, BIOX).

- Cyanidation: Gold recovery from oxidized tailings via CIL (65~75% gold recovery).

Typical Flow: Grinding → Bulk flotation → POX/BIOX → CIL → Electrowinning.

Case in Mongolia: Gold from the Oyu Tolgoi copper-gold mine is mainly recovered as a by-product of copper concentrate (annual output: 15~20 tons).

3. Oxidized Gold Ore Beneficiation Process

Major Mines: Khar Mod (Dornod Province), South Gobi deposits

Key Features

- Heap Leaching: Applied to low-grade ores (0.5~2 g/t gold) via NaCN solution percolation.

- Carbon-in-Pulp (CIP/CIL) Process:High-grade ores undergo cyanide leaching in agitated tanks (recovery >85%).

Typical Flow: Crushing → Agglomeration (preventing slimes) → Heap/agitation leaching → Carbon adsorption → Electrowinning.

Case in Mongolia: The Khar Mod gold mine uses heap leaching technology, producing about 1 ton of gold annually with a recovery rate of about 65%.

4. Refractory Gold Ore Beneficiation Process

Major Mines: Asgat (Altai region), some copper-gold tailings

Key Features

- Roasting Oxidation: Decomposes arsenic/sulfide-locked gold (arsenopyrite → Fe₂O₃ + SO₂) but requires gas treatment.

- BIOX (Bio-Oxidation): Uses acidophiles (e.g., Acidithiobacillus ferrooxidans) for sulfide oxidation (slow but eco-friendly).

Typical Flow: Grinding → BIOX/Roasting → CIL → Carbon adsorption.

5. Tailings Treatment & Environmental Considerations

Tailings Reprocessing: Old tailings in Mongolia (1~2 g/t Au) are retreated via flotation/gravity methods (e.g., Zaamar).

Cyanide-Free Alternatives: Thiosulfate Leaching: Tested in some Mongolian oxidized ores.

Mercury Pollution Control: Phasing out amalgamation in favor of gravity-smelting methods.

Summary of Gold Beneficiation Processes in Mongolia

Ore Type | Key Process | Critical Equipment | Recovery | Example Mines |

Placer Gold | Gravity separation | Knelson concentrator | 70~90% | Zaamar |

Quartz Vein | Gravity-Flotation-CIL | Ball mill, flotation cells | 85~95% | Boroo |

Porphyry Cu-Au | Bulk flotation + POX | Autoclave, flotation column | 60~75% (Au) | Oyu Tolgoi |

Oxidized Ore | Heap Leach/CIP | Heap pads, adsorption tanks | 50~80% | Khar Mod |

Refractory Ore | BIOX/Roasting + CIL | BIOX reactor | 70~85% | Asgat (potential) |

Challenges & Future Trends

1. Technical Barriers:

- Efficient pretreatment (e.g., for arsenic-rich ores) is lacking.

- Remote mines suffer from power shortages, limiting large-scale processing.

2. Environmental Regulations:

- EU “Conflict Minerals” rules restrict exports; cyanide-free methods are encouraged.

3. Innovations:

- Modular Processing Plants: Suitable for small/medium mines (e.g., Mongolian artisanal gold).

- Green Hydrometallurgy: Thiosulfate leaching under study by Mongolian Academy of Sciences.

Conclusion

In conclusion, Mongolia’s gold resources are widely distributed, with notable deposits in areas such as the Khangai Mountains and the Gobi Desert. The application of efficient gold beneficiation techniques—including gravity separation, flotation, and cyanidation—ensures economically viable and environmentally responsible extraction. As Mongolia continues to develop its mining sector, advancements in mineral processing technology and sustainable practices will play a vital role in maximizing gold recovery while minimizing environmental impact. Future efforts should focus on technological innovation and improved resource management to support the long-term growth of Mongolia’s gold mining industry.