Indonesia’s gold-rich regions continue to attract miners seeking profitable alluvial deposits, but efficiency and recovery rates remain top challenges. In Aceh, a state-of-the-art 50TPH alluvial gold processing plant has been successfully operationalized—combining high recovery rates (80-85%) with low maintenance requirements.

This blog examines how the plant operates, why specific equipment was selected, and what makes this setup ideal for small to medium-scale miners. Whether you’re an investor, miner, or industry enthusiast, this case study provides actionable insights into maximizing gold recovery while minimizing waste and costs.

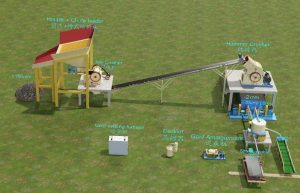

50TPH Alluvial Gold Processing Plant in Indonesia

Project Overview: A Lean, High-Efficiency Gold Processing System

Located near a riverbank in Aceh, Indonesia, this 50-ton-per-hour (TPH) processing plant specializes in fine alluvial gold (under 6mm) with minimal sticky clay contamination. Unlike complex hard-rock gold processing, the plant leverages gravity-based separation—proving that simplicity can drive profitability.

From hopper feeding to smelting, every stage is optimized for:

✔ High recovery rates (80-85%)

✔ Low water consumption (~150m³/h)

✔ Minimal operator intervention

✔ Cost-effective scalability

But first—what makes Aceh’s alluvial gold unique?

Understanding the Ore: Why Deposit Type Matters

The mine site contains loose, river-hosted alluvial gold, mainly in particles under 6mm. Unlike clay-heavy deposits that require intensive washing, Aceh’s gold is easily liberated, making trommel screening sufficient instead of scrubbers.

Crucially, the absence of large nuggets influenced equipment selection—centrifugal concentrators and shaking tables were prioritized over coarse recovery systems.

With geology accounted for, how does processing unfold?

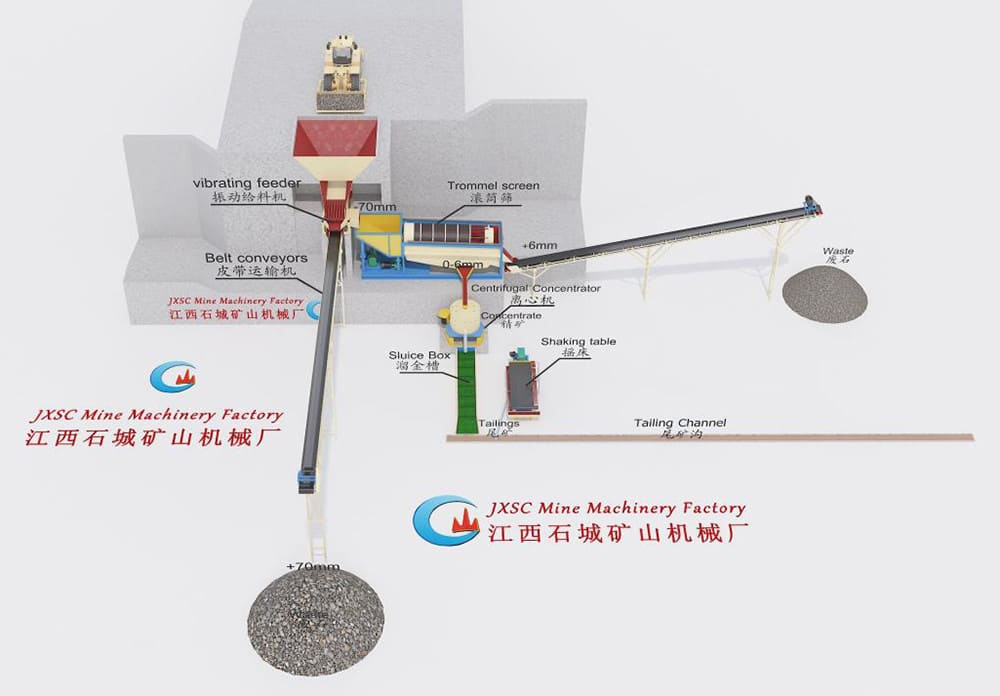

Step-by-Step Processing: Turning Raw Ore into Pure Gold

50TPH Alluvial Gold Processing Plant Process Description

1. Loader or excavator feeds raw ore to the hopper, then through the vibrating feeder smoothly feeds into the trommel screen. The vibrating feeder with a grizzly bar, gap 70mm. Above 70mm from the grizzly feeder are transported to a far place by belt conveyor.

2. Trommel screen with one layer of manganese steel screen, mesh size 6mm. The screen is used for washing clay, then the washed materials go to the screen for sieving out 0-6mm, and above 6mm.

3. Above 6mm from the trommel screen are transported to a far place by belt conveyor.

4. Centrifugal concentrator, shaking table and sluice box are a 0-6mm gold separator system. The 0-6mm material from the trommel screen will go to the centrifugal concentrator for roughly concentrating gold. Then the tailings from the concentrator will go to the sluice box for recovering more gold. The concentrate from the gold centrifugal concentrator will go to the shaking table for fine concentrate. In this way, customers can get as much as gold concentrate from this gold separator system.

5. Finally, all gold concentrates are sent to the gold smelting furnace for purification, so that customers can get a pure gold bar.

Main Equipment List

- Vibration Feeder

- Trommel Screen

- Gold Centrifugal Concentrator and Shaking Table

- Sluice Box

- Belt Conveyor

- Water Pumps & Gold Smelting Furnace

This flowchart has the following advantages:

- Gold recovery rate is very high, utilizes 1*sluice box and 1*big shaking table to recover the maximum amount of fine gold and coarse gold, all sizes of gold are recovered by this plant.

- The plant is suitable for any type of alluvial gold ore, such as heavy mud or clay ore, sticky clay ore, sandy ore, etc.

- Operation is simple, maintenance is few.

- Investment is less, payback is fast.

FAQ During Communication

Question 1: Is the vibrating feeder necessarily required?

Answer: It is not necessary to use it. However, the vibrating feeder is capable of achieving an input processing capacity of 50TPH. If the vibrating feeder is not used and the material is directly fed into the hopper of the trommel screen, then large stones will need to be manually removed, which will take some time and thus will not be able to achieve an input processing capacity of 50TPH.

Question 2: What is the gold recovery rate for the entire processing plant?

Answer: About 80-85%, it depends on your real mine site condition.

Question 3: Why are sluice boxes and shaking tables used behind the centrifugal concentrator?

Answer: The shaking table is used to further concentrate the gold concentrate from the centrifuge. Through continuous shaking, it sweeps away the excessive lighter impurities under the action of water. The sluice box is used to recover the tailings from the centrifuge to prevent any gold from being lost. Such a combination has significantly increased the recovery rate and quality of gold.

Question 4: What’s the water consumption of the whole processing plant?

Answer: The equipment that requires water during the process is: trommel screen, centrifugal concentrator, and shaking table. The total water consumption is about 150m3/h.

Question 5: Why use a trommel screen instead of a trommel scrubber?

Answer: Your alluvial gold is nearby river and with a little clay. The trommel screen is enough for washing it. If there is sticky clay, you can use the High-pressure water gun to wash it.

Question 6: Could you provide the basic drawings for the installation?

Answer: Sure. As long as the customer has placed an order, we will prepare the installation drawings based on the actual size of the equipment once it is ready.

Why This Setup Delivers Fast ROI?

- Lower upfront cost than large CIP/CIL plants

- High recovery without chemical use

- Easy operation—minimal training needed

Conclusion: A Blueprint for Small-Scale Gold Success

This Indonesian plant proves that smart design, not complexity, drives gold mining profits. By carefully matching equipment to ore type, miners achieve:

- High gold recovery with gravity methods

- Low operational costs

- Scalable expansion

For small-scale miners, simplicity + efficiency = profitability. Whether you’re exploring Aceh or similar regions, this 50TPH model offers a proven gold recovery blueprint.