The gold mining industry continues to evolve, with alluvial deposits remaining a significant source of accessible gold reserves worldwide. In Ghana, where alluvial gold mining contributes substantially to the economy, efficient processing methods are crucial for both large-scale operators and artisanal miners. This article explores effective processing techniques through a practical 5TPH alluvial gold plant case study, demonstrating how modern technology can maximize recovery while minimizing environmental impact.

Alluvial Gold in Ghana

Alluvial gold refers to naturally occurring gold particles deposited by river systems in Ghana, typically found in riverbeds, floodplains, and ancient waterways. Due to its relatively simple extraction methods, it plays a significant role in Ghana’s gold mining sector, supporting both small-scale miners and mechanized operations.

Key Locations

Major alluvial gold deposits are found in:

- West African Craton: A stable geological formation rich in gold.

- Ashanti Region: Traditional gold-mining hubs like Obuasi and Kumasi.

- Western Region: River sediments near Tarkwa and Prestea.

- Bono, Ahafo & Northern Regions: Emerging alluvial mining zones.

Ghana, Africa’s largest gold producer, boasts abundant alluvial gold deposits along its river systems and ancient terraces.

Characteristically

- Deposits contain free-milling gold particles ranging from fine dust to substantial nuggets

- Materials are typically loose and easy to process, often requiring minimal crushing

- Gold purity averages 85-95%, making Ghanaian alluvial gold particularly valuable

- Seasonal variations affect deposit accessibility, emphasizing the need for mobile processing solutions

Mining & Economic Impact

- Ghana is Africa’s second-largest gold producer(after South Africa), with alluvial gold contributing significantly.

- Artisanal and Small-scale Mining (ASM) accounts for ~30% of national gold output.

- Illegal mining (“Galamsey“) causes severe environmental damage (river pollution, deforestation).

Legal & Environmental Challenges

- The Minerals Commissionregulates mining licenses.

- The government seeks to curb illegal mining and promote eco-friendly methods (e.g., mercury-free processing).

Future Trends

- Increased mechanization (mobile plants, dredges) boosts efficiency.

- Foreign partnerships (China, South Africa) drive technology upgrades

Ghana possesses rich alluvial gold resources, but sustainable mining remains crucial for long-term benefits.

Methods for Processing Alluvial Gold in Ghana

The extraction and processing of alluvial gold in Ghana primarily involve small-scale artisanal mining and semi-mechanized operations. Common treatment methods include:

1. Traditional Gold Panning

Suitable for: Coarse gold particles

Process:

- Excavation: Extract gold-bearing sediment from riverbeds or floodplains.

- Screening: Remove large gravel using sieves.

- Panning: Wash the sand and water mixture in a pan, allowing heavier gold particles to settle at the bottom.

Advantages: Simple operation, low cost, suitable for individual miners.

Disadvantages: Low efficiency, risk of losing fine gold particles.

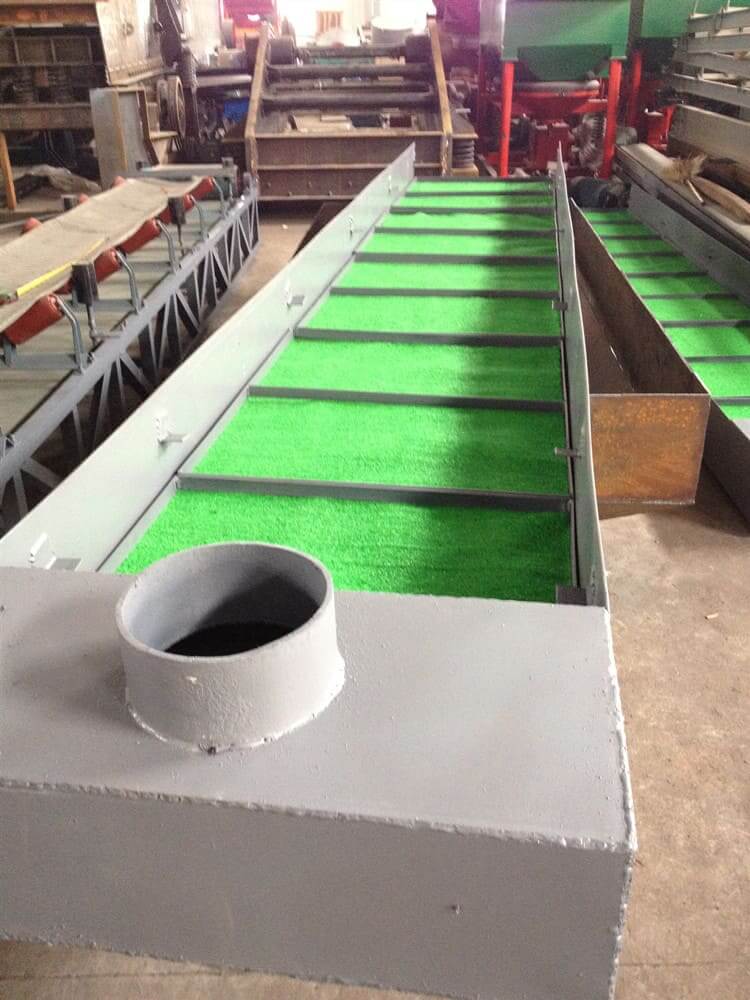

2. Sluice Box Processing

Suitable for: Small to medium-scale alluvial gold deposits

Equipment: Wooden or metal sluice boxes lined with riffles or gold-catching mats (e.g., coconut fiber or synthetic felt).

Process:

- Flushing sediment: Mix gold-bearing sand with water and feed it into the inclined sluice.

- Gravity separation: Water washes away lighter materials while gold particles are trapped by riffles/mats.

- Gold collection: Periodically clean the mats to recover concentrated gold.

Advantages: More efficient than panning, suitable for small-scale mining.

Disadvantages: Requires steady water flow, moderately complex operation.

3. Dredging

Suitable for: River or lake deposits

Equipment: Floating dredgers equipped with suction pumps and gravity separators.

Process:

- Sediment suction: Use underwater pumps to extract gold-bearing sand.

- Sieving: Pass the material through vibrating screens to remove large debris.

- Centrifugal enrichment: Separate gold using centrifuges or jig machines.

Advantages: High mechanization level, suitable for large-scale mining.

Disadvantages: High investment cost, potential ecological damage.

4. Cyanidation (for Fine Gold)

Suitable for: Fine gold (<0.1mm) or gold concentrate

Process:

- Crushing & grinding: Break ore into fine powder.

- Leaching: Dissolve gold in a sodium cyanide (NaCN) solution under alkaline conditions.

- Zinc precipitation: Add zinc powder to recover gold sludge, which is then smelted into gold bars.

Advantages: High recovery rate (~90%).

Disadvantages: Toxic chemicals require strict management.

5. Mercury Amalgamation (Restricted)

Common in artisanal mining but discouraged due to toxicity.

Process:

- Mixing mercury: Combine mercury with gold-bearing sand to form amalgam.

- Filtering: Remove excess mercury via squeezing.

- Heating: Burn off mercury vapor to obtain crude gold.

Issues: Severe mercury pollution harms health & the environment.

Alternatives: Promote mercury-free technologies (e.g., spiral concentrators).

6. Gravity Separation Equipment (Shaking Tables, Centrifuges)

Suitable for: High-grade deposits or commercial-scale mining

Devices: Shaking tables, Knelson concentrators, etc.

Principle: Utilize density differences between gold and waste rock for separation.

Environmental & Legal Regulations

Ban on illegal mining: The Ghanaian government cracks down on unauthorized “Galamsey” activities.

Mercury reduction: Promotion of cyanide/mercury-free alternatives (e.g., Borax method).

Land rehabilitation: Mine sites must be restored post-extraction.

Case Study: 5TPH Alluvial Gold Process Plants In Ghana

The mine site is located in Ghana. The raw materials details are as follows:

- Alluvial gold with no sticky clay

- Capacity 5tons per hour

- Gold concentrate size most 0-3mm, has some nuggets

Questions & Answers

Q: Can the machines do self-washing and be mobile?

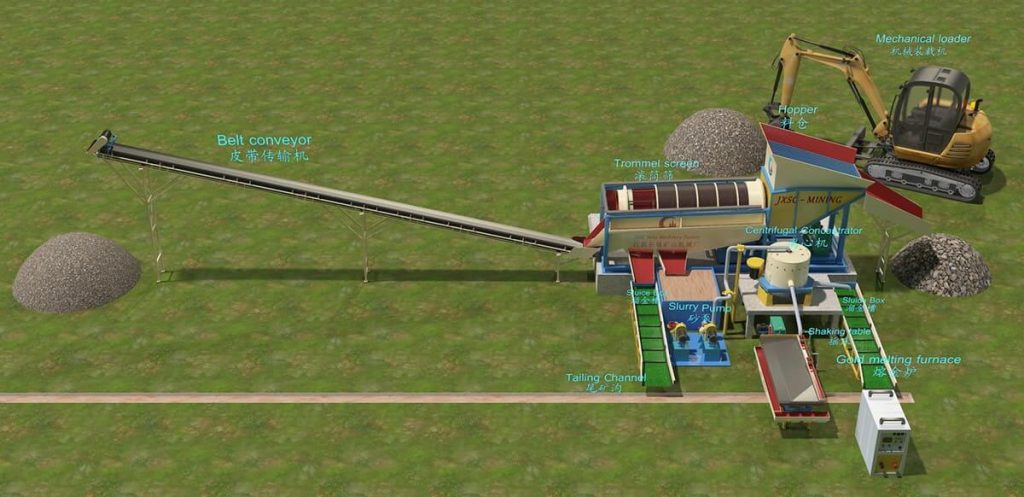

A: Yes, when the materials feed into the hopper of the trommel screen, the trommel will rotate, and when you add the water, the materials will be washed clean. And the trommel can be a mobile type, as shown below.

Q: How can I get the gold concentrate size 0-3mm and the nuggets?

A: The screen mesh of the trommel can be customized. If your gold concentrate size is 0-3mm, the screen mesh size will be made of 3mm; if the nugget size is 10mm, another screen mesh of 10mm. Typically, the screen mesh consists of two layers.

After sieving the size 0-3mm and 3-10mm, the 0-3mm will go to the gold centrifugal concentrator to get the gold concentrate, and the 3-10mm will go to the gold sluice box to get the gold concentrate.

Q: How much water will be needed?

A: The water consumption is 2-3 times the process capacity. If the process capacity is 5tons per hour, the water consumption will approx 10-15m³ per hour.

Our 5TPH Alluvial Gold Process Plant Design

Based on the customer’s condition, below is the flowchart we recommend

- Trommel screen for washing the raw materials, and sieve the sizes 0-3mm and 3-12mm to different separator machines.

- Gold centrifugal concentrator for processing the 0-3mm materials to get the gold concentrate.

- Gold sluice box 1# for processing the 3-12mm materials to get the gold concentrate.

- Gold sluice box 2# for recovering the gold from the tailing of the Gold centrifugal concentrator.

- Shaking table for refining the gold concentrate from the Gold centrifugal concentrator.

- The gold smelting furnace is for smelting the gold particles to gold bar.

- Belt conveyor for transporting the +12mm materials to the waste pile.

Conclusion

This 5TPH processing solution demonstrates how carefully designed circuits can optimize gold recovery from Ghanaian alluvial deposits. By combining classification, gravity separation, and thorough tailings management, operators achieve:

- High recovery rates across all particle sizes

- Water efficiency (10-15m³/hour)

- Mobility for seasonal relocation

- Environmentally responsible operation

As Ghana continues to formalize its small-scale mining sector, such efficient processing plants set the standard for sustainable, profitable alluvial gold recovery. Future advancements may incorporate modular designs and automated controls, further improving recovery rates and operational efficiency in West Africa’s goldfields.