Tanzania’s 1,424-kilometer Indian Ocean coastline contains world-class placer resources and is an important global producer of titanium, zircon, and rutile. This article deeply analyzes its geological origin, economic value, development potential, and mineral processing process.

Exploring Tanzania's Coastal Sand Mines: Rare Wealth on The East African Coastline

Coastal sand mines (or heavy mineral sand deposits) are coastal sites where dense, valuable minerals like ilmenite, rutile, and zircon are extracted. These minerals contain critical industrial elements such as titanium, zirconium, and rare earths.

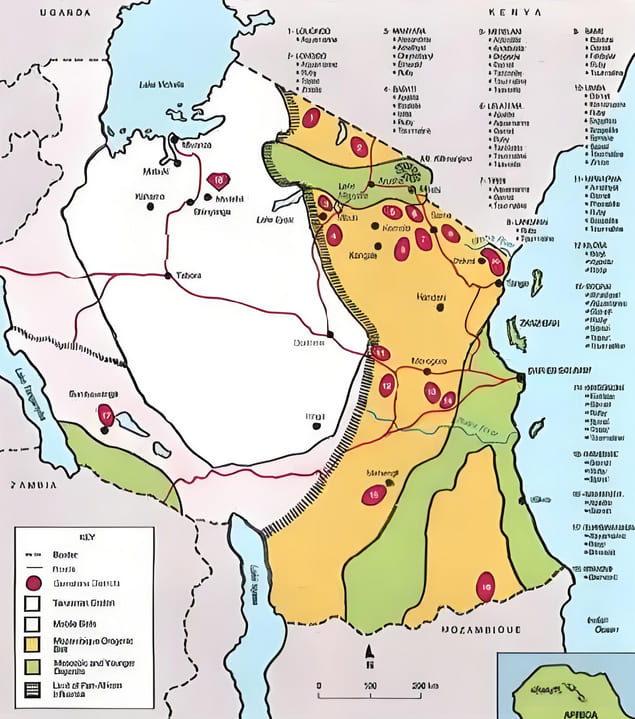

Distribution of core sand mine resources

Main mining areas

- Mtwara coastal belt: ilmenite content is as high as 60%

- Tanga northern mining area: zircon reserves account for 75% of the country

- Rufiji Delta: sand layers containing rare earth elements (REE)

Typical mineral combination

- Heavy mineral ratio: 8-15% (international average level 3-5%)

- Each ton of sand mine contains:

- Ilmenite: 120-180kg

- Rutile: 15-30kg

- Zircon: 40-65kg

Geological Origin Analysis

Formation Mechanism

- Ancient metamorphic rocks (Usagara belt) were transported by rivers

- The sorting effect of Indian Ocean monsoon currents

- Natural enrichment effect of the coral reef system

Ore layer characteristics

- Average thickness: 2.3-4.5 meters

- Occurrence depth: intertidal zone to 15 meters underwater

- Typical particle size: 0.1-0.3mm (optimal ore size)

Economic and industrial status

Mining data (2023)

- Annual output: 8 million tons of titanium concentrate (7th in the world)

- Export value: 12% of foreign exchange income from minerals

- Main buyers: China (62%), India (18%), EU (15%)

Benchmark enterprises

- China Wuyi Mining (Mbeya Project)

- Australia Base Resources (Coastal Concession Area)

- Local Tanzanite One Consortium

Key points of the environment and regulations

Ecological protection measures

- Use mobile wet sorting (reduce water consumption by 40%)

- Force vegetation restoration in mining areas (coverage rate ≥ 80% within 3 years)

Investment policy

- Royalties: 5% for concentrate/3% for coarse ore

- Local shareholding requirements: at least 16%

- New regulations: prohibition of raw ore export from 2024

In-depth Q&A

Q1: Why is the grade of Tanzanian coastal sand mine outstanding?

Answer: Unique history of ancient coastal uplift + strong weathering in the equatorial region.

Q2: Can individuals participate in the small-scale collection?

Answer: An Artisanal Mining License (up to 5 hectares) must be applied for.

Tanzania Seaside Sand Ore Processing: Roughing to Concentrating

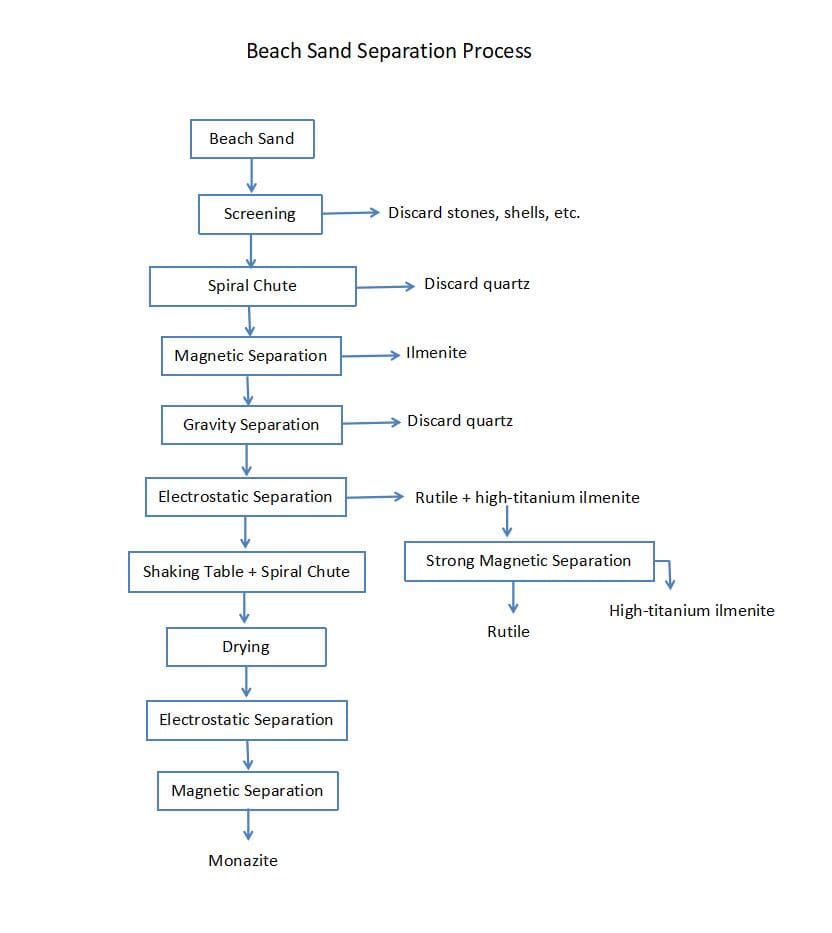

Tanzania in Africa has rich coastal sand ore resources, the main minerals include ilmenite, rutile, zircon, monazite, etc., with high monomer dissociation degree, coarse particle size (>0.1mm), and high heavy mineral content (2~3kg/t). Since coastal sand ore does not require crushing and grinding, it is usually separated by a combined process of “gravity separation-magnetic separation-electric separation”. The specific process is as follows:

1. Roughing Stage (recovery rate ≥95%)

Goal: Remove light minerals (quartz, feldspar, etc.) and enrich heavy minerals (ilmenite, zircon, monazite, etc.).

Applicable equipment: rotary screen, vibrating screen, spiral chute, shaking table, etc..

Ore Pretreatment

Hydraulic mining: high-pressure water pumps (15- 20MPa) flush the ore sand layer to form a slurry (solid-liquid ratio 1:8)

Primary screening:

- Rotating sieve (aperture 50mm) to remove shells/gravel.

- High-frequency vibrating screen (2mm) to separate clay particles

Tanzania features: Using tidal energy to drive the screening system (Lindi Port project saves 30% of electricity)

Spiral Roughing(gravity separation and tailings discarding)

Spiral chute (high efficiency, low cost, suitable for coarse particle separation)

Key parameters:

- Slurry density: 1.6-1.8g/cm³

- Inclination: 9-12° (automatically adjusted with tidal water level)

Output:

- Heavy sand concentrate (containing heavy minerals ≥75%)

- Tailings (siliceous sand>90%, directly used for land reclamation)

Shaking table (fine separation, improve heavy mineral recovery rate)

Process description:

After the raw ore is screened to remove large particles of impurities, it enters the spiral chute or shaking table for gravity separation to obtain coarse concentrate (heavy minerals), and the tailings (quartz sand, etc.) are directly discharged or used as building materials.

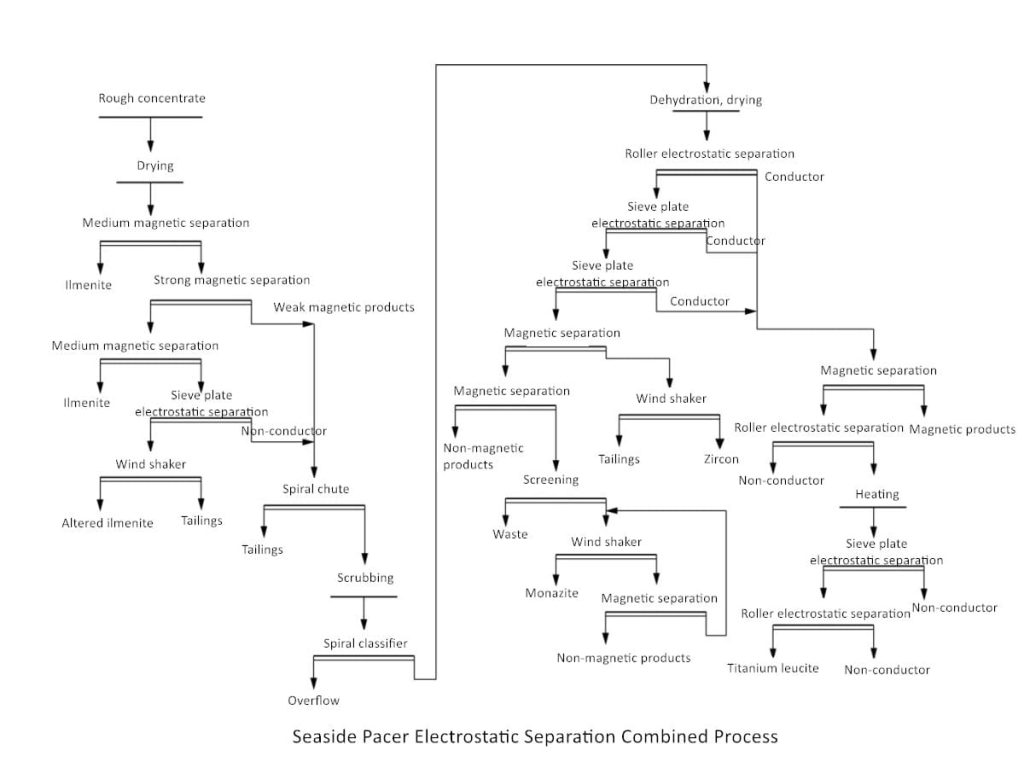

2. Concentration Stage (grade improves 3-5 times)

Target: Separation of valuable minerals such as ilmenite, zircon, monazite, rutile, etc.

(1) Magnetic separation of ilmenite

Strong magnetic separation: The coarse concentrate is first separated by a dry/wet strong magnetic separator to separate the ilmenite (strong magnetic property).

Medium magnetic separation: The remaining material enters the medium magnetic separation to separate the altered ilmenite or magnetite.

Wet magnetic separation (except ilmenite)

- Equipment: Permanent magnetic drum (field strength 0.8-1.2T)

- Typical indicators: Ilmenite recovery rate: 92-96%; Tailings TiO₂ content: ≤5%.

(2) Electrostatic separation of non-magnetic minerals

High-voltage electrostatic separation: Weakly magnetic and non-magnetic minerals (zircon, monazite, rutile, etc.) enter the electrostatic separator and are separated by using the difference in mineral conductivity:

- Conductive minerals (rutile, titanium dioxide): adsorbed by the electrode and enter the conductive product.

- Non-conductive minerals (zircon, monazite): not affected by the electric field and fall into the non-conductive product.

Process conditions

- Electrode voltage: 25- 40kV

- Drum speed: 120- 150 rpm

- Temperature control: 80±5℃ (special cooling is required in the high-temperature environment of the Indian Ocean)

Separation efficiency

- Zircon ZrO₂ purity: ≥95%

- Rutile TiO₂ grade: ≥88%

(3) Reprocessing and fine separation

Conductive minerals (rutile, etc.): can be further purified by magnetic separation or electrostatic separation.

Non-conductive minerals (zircon, monazite): Spiral chute + shaking table: improve zircon grade.

(4) Flotation purification (optional process)

For rare earth element enrichment

- Collector: sodium hydroxamate (dosage 200-400g/t)

- pH adjustment: sodium carbonate to 8.5-9.0

- Number of times of concentration: 3-5 times (to reach Nd₂O₃≥60%)

3. Concentrate processing

(1) Dehydration and drying

Two-stage process:

Cyclone (dehydration to 25% moisture content)

Solar drying shed (Tanzania sunshine advantage, 48 hours to ≦2% moisture)

(2) Grading packaging

International standard sorting

- Ilmenite: -100 mesh ~ +200 mesh (mainstream specifications in the global market)

- Zircon: 5 grades according to ASTM C622

(3) Anti-damage packaging

- Ton bag + inner film (moisture-sensitive minerals)

- Silica gel desiccant is laid on the bottom of the container

Typical process flow of seaside sand mine

The optimized process of the seaside sand mine is as follows:

- Ore → Screening (removing coarse sand) → Spiral chute/shaking table (gravity separation and tailings discarding) → Rough concentrate

- Rough concentrate → Strong magnetic separation (ilmenite) → Medium magnetic separation (altered ilmenite)

- Non-magnetic minerals → Electrostatic separation (separation of conductors/non-conductors)

- Conductor minerals (rutile, titanium dioxide) → Magnetic separation + Electrostatic separation purification

- Non-conductor minerals (zircon, monazite) → Magnetic separation + Shaking table separation

- Final products

- Ilmenite (TiO₂ >48%)

- Rutile (TiO₂ >90%)

- Zircon (ZrO₂ >65%)

- Monazite (rare earth concentrate)

Conclusion

For coastal heavy mineral sand deposits, a combined gravity-magnetic-electrostatic separation process is the preferred beneficiation method. This integrated approach offers distinct advantages—low capital investment, reduced energy consumption, and high recovery rates—making it an economically viable solution for large-scale industrial operations. The process efficiently separates high-value minerals such as ilmenite, zircon, and monazite, maximizing resource utilization while maintaining cost-effectiveness.