Are you having trouble deciding between left-type and right-type shaking tables for your mineral processing line? These seemingly similar equipment have critical differences that directly impact separation efficiency and operational costs. With 20 years of manufacturing experience, we’ve seen many clients suffer losses due to poor choices.

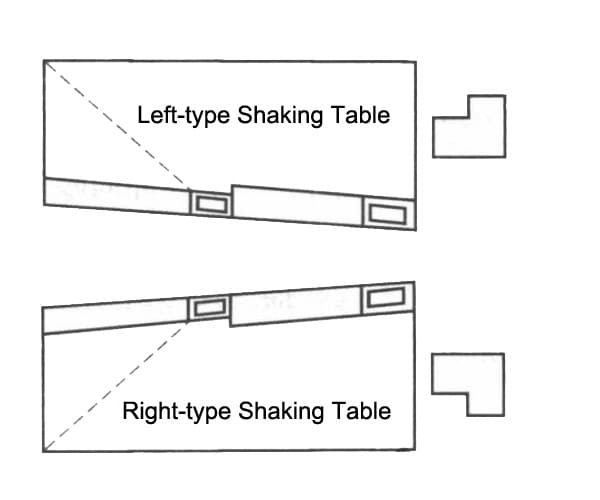

The key difference between left and right-type shaking tables lies in the drive mechanism position – left-sided tables have drives on the operator’s left, while right-sided ones place drives on the right. This fundamentally changes ore flow direction, operating habits, and plant layout requirements. Right-sided models suit right-handed operators better, while left-sided versions fit specific workshop configurations.

Left-Type VS Right-Type Shaking Table

The distinction between left and right-type shaking tables is based on the position of the ore feeding chute. But the positioning difference is just the beginning. To make the optimal choice, you need to understand more deeper levels of comparison that most suppliers won’t tell you.

Different Definitions

From time to time, customers and friends ask how to distinguish the left and right directions of the mineral processing shaking table. Today we will analyze this problem for you in detail. Some customers using mineral processing shaking tables due to site constraints, must ensure that the feeding direction is fixed, otherwise it will affect the transportation of materials. Therefore, the direction of the mineral processing shaking table is crucial, and the basis for its determination mainly depends on the feeding end of the bed.

Specific identification methods are as follows: stand in front of the head gearbox of the concentrator shaker, facing the bed, such as the feed port is located on the left side, this is the left shaker; on the contrary, if the feed port is located on the right side, it is called the right shaker.

Structural Differences Breakdown

| Item | Left-type Shaking Table | Right-type Shaking Table |

| Bed Head Position | From the feeding end, the bed head is on the left. | From the feeding end, the bed head is on the right. |

| Drive position | Left of operator | Right of operator |

| Standard rotation | Counter-clockwise | Clockwise |

| Feed direction | Right-to-left | Left-to-right |

| Bed Movement Direction | The bed surface reciprocates asymmetrically from the left front to the right back (right tilted). | The bed surface reciprocates asymmetrically from the right front to the left back (left tilt). |

| Concentrate enrichment direction | Usually moves more to the right | Usually moves more to the left |

| Tailing discharge direction | Left side is more obvious | Right side is more obvious |

| Use Characteristics | Traditional design, suitable for most ore sorting. | Rarely seen for special ore or process requirements. |

For the case of two or more ore dressing shaking tables, it is usually recommended to adopt a parallel layout of one on the left and one on the right, so that the discharge ports of each ore dressing shaking table face each other and maintain a distance of about 30 cm to set up tailings receiving troughs of uniform material. Such an arrangement is conducive to space utilization and greatly simplifies the management and operation process.

Differences in Operation & Maintenance

The core difference between left-type and right-type shaking tables in operation and maintenance stems from the difference in equipment layout, which is mainly reflected in the difference in the direction of the operating space, the location of components, and the maintenance route. The specific comparison is as follows:

1. Operation difference

The operation space direction is opposite

Left-type shaking table: The feed chute is located on the left side of the bed head, and the operation channel is usually located on the right side, which is convenient for personnel to stand and adjust the stroke, slope, and flushing water.

Right-type shaking table: The feed chute is located on the right side of the bed head, and the operation channel is biased to the left side. When maintaining, the core components need to be approached from the left.

Adjustment component position difference

The position of control components such as the stroke handwheel, slope adjustment handwheel, and flushing water diverter valve will be mirror-symmetrical with the left-right layout, and attention should be paid to the direction adaptation during operation.

2. Maintenance difference

Different maintenance routes of the feeding system

The left-type shaking table needs to focus on the maintenance of the left-side feed chute and water pipe, while the right-type needs to focus on the right-side pipeline, and the replacement path of worn parts is the opposite.

Transmission mechanism maintenance direction

When maintaining the headstock (transmission mechanism), the left-hand type needs to enter the maintenance area from the right, the right-hand type needs to enter from the left, and the tool placement needs to be adjusted.

3. Common maintenance requirements

Although the layout is different, the core operation and maintenance process are consistent:

- Stroke adjustment: Both use handwheels or screw rods to adjust the position of the toggle plate seat/rocker arm;

- Slope and water film control:Both rely on the slope adjustment handwheel and water diversion valve to adjust the lateral slope and water flow distribution;

- Lubrication and consumables: The lubrication cycle and replacement standards of the headstock gear, support slider, and other components are exactly the same.

Application Scenario Comparison

The left-type and right-type shaking tables are essentially mirror-symmetrical designs. The core difference in operation and maintenance is only the reversal of the spatial direction, which does not affect the function and performance. When choosing, you need to match the left and right types according to the workshop layout to avoid conflicts in the operation lines.

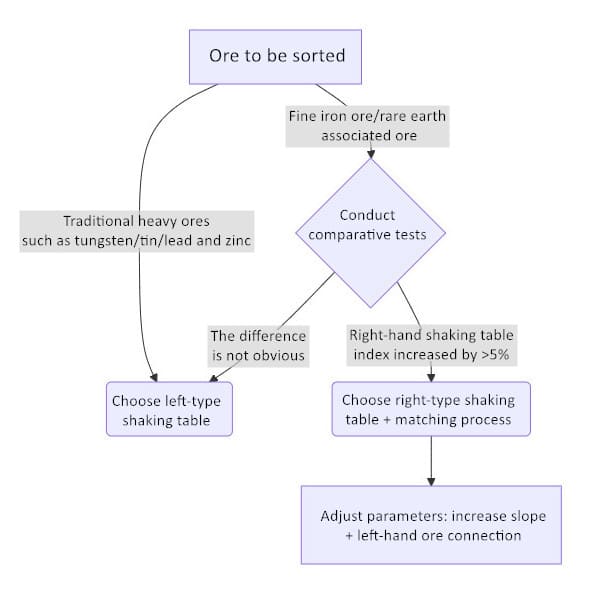

The comparison of the application scenarios of the left and right ore dressing shakers is mainly reflected in the differences in their applicable minerals. The feed trough of the left shaker is on the left, while the feed trough of the right shaker is on the right. This design difference determines their application effects in different scenarios.

Applicable minerals

Left shaker: Suitable for processing higher-grade minerals, such as iron ore, titanium ore, manganese ore, etc. Due to its structural characteristics, the left shaker performs well in processing these minerals and can effectively carry out preliminary enrichment.

Right shaker: More suitable for processing low-grade minerals, such as tungsten ore, tin ore, etc. The right shaker can directly select the final concentrate through one-time or multiple continuous sorting, so it has significant advantages in processing low-grade minerals.

Sorting efficiency and processing capacity

Left shaker: Suitable for processing materials with a particle size range of 0.3-0.02 mm, with strong processing capacity, suitable for sorting coarse and fine particles of minerals.

Right-type shaker: Suitable for processing materials with a particle size of 0.22-2 mm, with high sorting efficiency, but relatively low processing capacity.

Installation and floor space

Left-type shaker: The installation process is relatively complicated, but the floor space is small, and suitable for sites with limited space.

Right-type shaker: Simple installation but complex structure, requires precise adjustment and operation, and occupies a large area.

Conclusion

The core difference between left and right shaking tables lies only in the difference in the transmission device and the inclination direction of the bed surface: the transmission mechanism of the left shaking table is on the left, and the ore particles move to the lower left, while the transmission mechanism of the right shaking table is on the right, and the ore particles move to the lower right. The separation principle and efficiency of the two are the same. The selection mainly depends on the process layout (such as the connection between upstream and downstream equipment), plant space limitations (equipment arrangement and operation channels) and operating habits. There is no difference in performance. The key is to match the actual production needs.

We are a mining equipment manufacturer with two decades of expertise in shaking table technology. Our engineers can help you select and optimize the perfect shaking table solution for your mineral processing needs.