In Zimbabwe’s competitive mining landscape, selecting the right processing plant supplier can make or break profitability. For one Chinese investor specializing in chrome concentrate, the decision came down to expertise, efficiency, and proven results—leading them to partner with us.

This case study explores why they chose us to design and supply a 50TPH alluvial chrome processing plant, delving into the project’s challenges, solutions, and the unique advantages that set us apart.

50TPH Alluvial Chrome Ore Process Plant In Zimbabwe

Project Background

The investor’s company primarily deals with purchasing chrome concentrate from various suppliers while also operating washing plants in Zimbabwe and South Africa. Recognizing an opportunity to increase self-supply and reduce dependency on external sellers, they sought a reliable, high-performance processing solution tailored to Zimbabwean alluvial chrome deposits.

Raw Ore Conditions & Customer’s Requirements

1. Plant feeding capacity: 50 TPH

2. Maximum feeding size of ROM: 150mm

3. Ore type: Red soil, alluvial chrome ore

4. Chrome concentrate size is 0-2mm

5. Average chrome grade in ROM is 10%

6. Target chrome concentrate grade is 48%

7. Customer requires for magnetic separator to reduce the iron content to increase the Cr/Fe ratio

Why JXSC? The Decision Drivers

1. Custom-Tailored Solution from Day One

Rather than offering a generic plant design, JXSC conducted a detailed ore analysis and adjusted every stage—from screening to magnetic separation—to maximize recovery (60%) and grade (48%).

2. Optimized Process Design

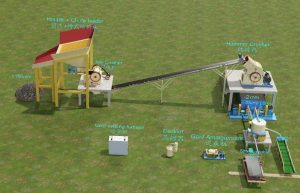

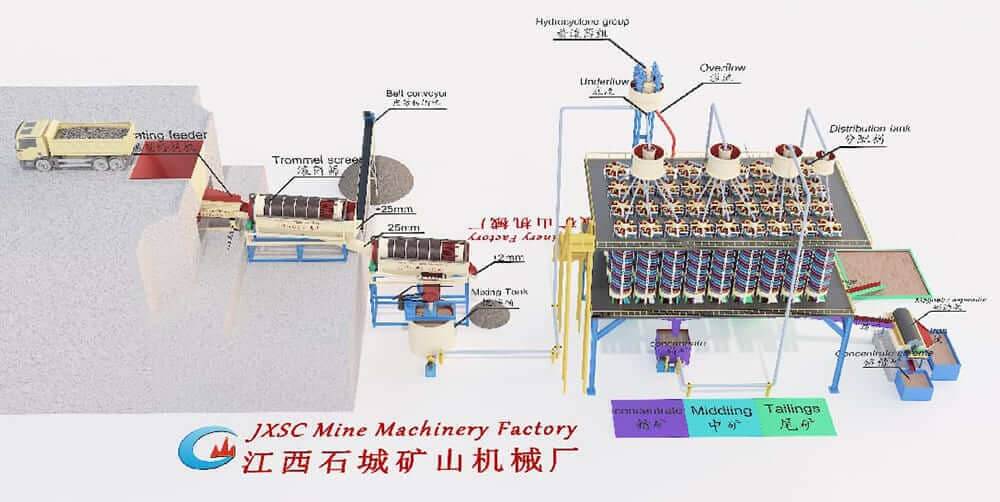

This flowchart design is for a complete alluvial chrome ore processing plant, including the vibrating feeder, two-stage trommel screening, spiral separation system, and magnetic separation system.

The detailed process is as follows:

(1) ROM is unloaded to the raw material hopper by a dumper truck. Customer build a feeding platform with a concrete build an embedded silo on the feeding platform. Our vibrating feeder is installed underneath the silo to smoothly feed raw ore to first stage trommel screen.

(2) First Stage Trommel screen: it is a wet screening, has 25mm steel bar mesh, it can flush the soil, and screen out 0-25mm and above 25mm gravel stone, which are transported to waste stockpile by belt conveyor.

(3) Second Stage Trommel Screen: It is a wet screening, has 2mm stainless steel slotted mesh, it can further flush the ore and screen out 0-2mm and above 2mm waste. Here customer doesn’t require a belt conveyor to transport +2mm waste. The waste (2-25mm) will be directly dropped on the ground.

(4) Less than 2mm from the second-stage trommel screen is pumped to the spiral chute separator for gravity beneficiation to remove impurities. The spiral chute separator has four stages: rougher spirals, scanner spirals, cleaner spirals, and re-cleaner spirals.

The middling & tailing of rougher spirals are pumped scanner spirals for beneficiation again. This design can increase the recovery rate.

The concentrate of rougher spirals and scanner spirals is pumped to cleaner spirals for final cleaning and beneficiation. This design can further increase the chrome concentrate grade.

The middling & tailing of cleaner spirals are pumped to re-cleaner spirals for beneficiation again, this design can increase the recovery rate.

(5) All concentrate from the cleaner spirals and re-cleaner spirals are going to the magnetic separator for reducing iron content, to increase the Cr/Fe ratio. The customer can get the target chrome concentrate from this stage.

Features of this plant design

This flowchart design uses two stages of trommel screening, four stages of spiral separation, and magnetic separation to reduce impurities and iron ore so as to improve the grade of chrome concentrate to meet the customer’s target grade.

This process technology is already mature and widely used in processing alluvial chrome ore, what’s more gained most customers’ recognition and good feedback. This plant design is professional & efficient & cost-effective.

This Plant Applicable Clients

✔ Suitable For

- Various types of sandy ore mining projects, such as alluvial chrome, beach sand, alluvial tin & coltan ore, etc.

- Alluvial raw ore without very much or very heavy sticky clay.

- Capacity can be customized as per requirement, from small-scale 5tph, 10tph to large-scale 100tph, 150tph, 200tph.

✖ Not Suitable For

- Rocky ore

- Materials with very much or very heavy sticky clay

3. Proven Equipment Reliability

We provided industry-trusted machines, including:

- GT Series Trommel Screens → Heavy-duty washing for clay-rich ore

- 5LL-1200 Spiral Chutes → Four-stage refining boosts concentrate purity

- CTB6018 Magnetic Separator → Reduces iron contamination effectively

Main Machines & Accessories

| No. | Name | Model | QTY (set) |

| 1 | Vibrating Feeder | DN380*96 | 1 |

| 2 | Trommel Screen | GT1550 | 1 |

| 3 | Trommel Screen | GT1545 | 1 |

| 4 | Spiral Chute Separator | 5LL-1200 | 36 |

| 5 | 1# 2# Distribution Tank | 1500*1200 | 2 |

| 6 | 3# Distribution Tank | 1000*1000 | 1 |

| 7 | 4# Distribution Tank | 800*800 | 1 |

| 8 | Magnetic Separator | CTB6018 | 1 |

| 9 | Slurry Pump | 6/4-AH | 2 |

| 10 | Slurry Pump | 4/3-AH | 1 |

| 11 | Slurry Pump | 3/2-AH | 1 |

| 12 | Mixing Tank | 2000×1800 | 1 |

| 13 | Hydrocyclone | FX350 | 4 |

| 14 | Belt Conveyor | B650*15m | 1 |

| 15 | Electric control cabinet | Control the start and stop of the plant equipment. Complete set electric control panels for the All machines | 1 |

| 16 | Spare Parts | 1 set spare parts for the plant equipment | 1 |

4. End-to-End Support

Beyond equipment supply, we delivered:

- 3D plant layout & foundation drawings → Smooth installation

- On-site/remote commissioning support → Minimizing downtime

- Technical guidance → Continuous optimization post-installation

5. Cost Efficiency Without Compromise

By balancing high recovery rates with low operational costs, the investor achieved faster ROI compared to competitors’ solutions.

Customer Questions & Our Answers

① Can you do a beneficiation test in your factory?

JXSC reply: Yes, we can do a beneficiation test in our factory.

② What is the recovery rate for the chrome wash plant?

JXSC reply: The recovery rate for this chrome wash plant is around 60%.

③ What is the final concentrate grade after processing by your wash plant?

JXSC reply: Based on your raw ore grade of 15-17%, the final concentrate grade can reach 48% plus.

④ Do you have a magnetic separator to reduce iron content from chrome ore?

JXSC reply: Yes, we suggest a drum-type wet magnetic separator with 1800-2000 gauss to reduce iron from chrome ore.

⑤ Do you have any technology for desliming? Because my raw ore is Laterite Chrome Ore, which has much clay inside.

JXSC reply: Yes, we suggest to add hydrocyclone in front of the spiral separator. The hydrocyclone can effectively desliming and make the spiral separator system reach the optimal separation efficiency.

The Outcome: A High-Performance Chrome Plant

After arriving in Zimbabwe (November 2025), the plant underwent final installation and is expected to deliver:

- 48%+ chrome concentrate from originally 10% feed grade

- Controlled iron levels, improving marketability

- Low maintenance & energy-efficient operation

Conclusion

For this Chinese investor, choosing JXSC wasn’t merely about acquiring machinery—it was about securing a long-term partner with deep chrome expertise, adaptable solutions, and unwavering post-sale commitment.

Looking for a trusted mineral processing partner?

Contact JXSC for a customized chrome plant assessment!