How can the efficiency of barite mineral processing be improved by optimizing this paragraph?

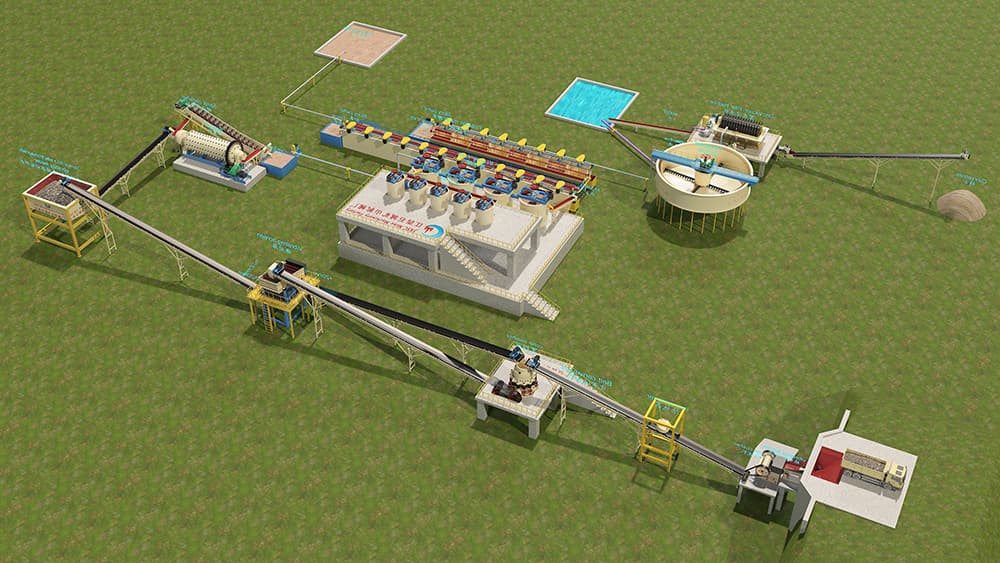

To improve the efficiency of barite beneficiation, careful preparation is required for the following key steps: ore property analysis, selection of beneficiation methods, preliminary design, environmental and economic benefits assessment, and design review and implementation. Through these steps, it can be ensured that the mineral processing plant can meet production needs while taking into account […]