The main hard rock ores that can be used to extract lithium are: spodumene, lepidolite, petalite, amblygonite, and eucryptite. This type of stone ore needs to be crushed before beneficiation.

Common beneficiation methods for lithium ore include flotation, heavy-media separation, and combined beneficiation.

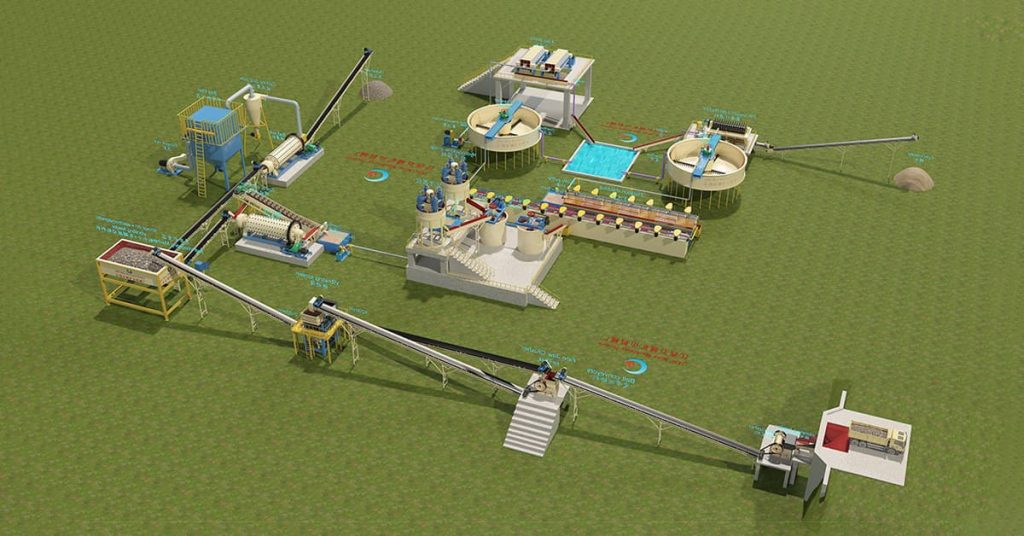

1. Lithium ore flotation process

Flotation is a common method for lithium ore selection. Common lithium ore flotation methods include direct flotation and reverse flotation.

Lithium ore Direct flotation: First, grind the lithium ore with a mill and add strong alkali for flotation. After high concentration, strong stirring, multiple scrubbing and desludging in an alkaline medium, oleic acid and its soap salts are added as collectors to directly float out the lithium concentrate, and the gangue minerals remain in the tank. No inhibitors are required in this process.

Reverse flotation of lithium ore: The reverse flotation method uses lime to create an alkaline environment, adds starch, dextrin, etc. to inhibit the floating of lithium ore, and uses cationic collectors to float silicate gangue minerals to the surface of the slurry. The product in the flotation machine tank is lithium concentrate. If the lithium ore contains iron minerals, a frother (such as HF, resinate) can be added to further help remove impurities such as iron minerals.

2. Heavy-media separation of lithium ore

The specific gravity difference between lithium ore and gangue minerals is not large, so it is not suitable to use a shaking table or jig separator. The heavy-media separation method is a good choice.

The lithium ore after washing and desludging is mixed with the heavy medium and fed into the heavy medium cyclone for separation. The heavy minerals and gangue minerals will be separated in the heavy medium. The heavy product will become lithium concentrate after being de-slurried by the de-slurry screen, and the gangue minerals will become tailings after being de-slurried.

3. Combined beneficiation of lithium ore

In actual beneficiation, the associated components of lithium ore are often very complex, and sometimes a single beneficiation method is difficult to obtain a good recovery effect. When necessary, a combined process can be used for separation. Such as: flotation-magnetic separation process, flotation-gravity separation-magnetic separation process, flotation-chemical treatment process, etc.

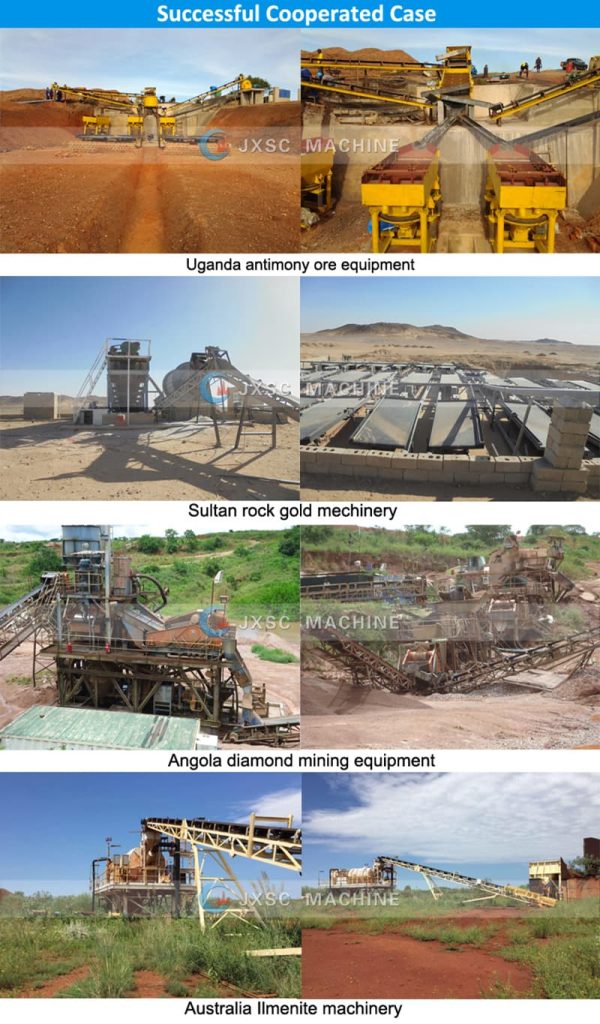

The above are common beneficiation methods for lithium ore. Lithium ore sample tests can also be carried out before production. JXSC has an ore testing laboratory and can provide all the equipment and technical support required for beneficiation. Welcome to consult and visit our factory.