Against the backdrop of an accelerating global energy transition, lithium has emerged as the “white oil of the 21st century” with strategic significance. According to Benchmark Mineral Intelligence, global lithium-ion battery demand surged by 65% YoY in 2023, driving rapid development of lithium resources. However, distinct metallurgical challenges exist across deposit types (hard rock/brine/clay) — while Australia’s Greenbushes pegmatite boasts processing costs just one-third of China’s brine operations, Chile’s Atacama salt flats still grapple with magnesium-lithium separation. This report systematically deconstructs the full production chain from exploration to final products, addressing critical bottlenecks like spodumene flotation selectivity (<80%) and low brine recovery rates (40-60%).

Lithium is a rare metal ore that generally requires beneficiation to produce qualified concentrate products suitable for smelting. Certain refractory ores amenable to hydrometallurgical processing can be smelted directly.

Lithium Ore Exploration

During geological exploration, preliminary ore deposits should undergo initial beneficiability tests, while detailed exploration deposits should undergo laboratory-scale continuous tests. For certain new types of deposits with complex material compositions, beneficiation tests should be conducted in advance to determine ore beneficiability and evaluate whether the deposit warrants further exploration. When industrial sectors require semi-industrial or industrial test samples and other experimental samples, geological exploration units shall collaborate with testing units to develop a sampling design for the deposit, provide geological data, and ensure proper coordination for the sampling activities.

Integrated Exploration and Metallurgical Testing

Per DZ/T 0203-2020 Rare Metal Mineral Exploration Standards, lithium prospecting mandates staged beneficiation tests:

Stage-Specific Protocols

Reconnaissance: Conduct heavy mineral separation (sample ≥50kg) to determine ore density (pegmatite: 2.8-3.2g/cm³) and liberation degree

Detailed Survey: Perform 72-hour locked-cycle tests evaluating:

- Optimal spodumene flotation pH (11-12 via Na₂CO₃ adjustment)

- Collector formulation (3:1 oleate-dodecylamine boosts recovery 15%)

- Grind size (-0.074mm ≥65-75%)

Complex Deposit Handling

For atypical deposits like Jiangxi’s lepidolite-rich ores:

- Autoclave leaching(230-250°C, 98% H₂SO₄)

- Roast-leach comparisons(sulfation vs. chlorination)

Industrial sampling requires:

- Pilot-scale samples: 0.01-0.05% of deposit volume

- Brine sampling: Stratified collection (≤0.5m intervals)

Case: Tibet’s Jieze Chaka Salt Lake achieved Mg/Li selectivity of 12.5 through adsorption-membrane hybrid tests during exploration.

Evolution of Lithium Mining Methods

Hard Rock Extraction

| Method | Applicability | KPI | Benchmark |

| Open-pit | Depth <300m | Stripping ratio ≤8:1 | Pilgangoora, AU |

| Room-and-pillar | Dip >45° | Pillar size 6×8m | Tanco, CA |

| Block caving | Massive ores | Fragmentation <0.5m³ | Manono, CD |

Differences in Lithium Mining Technologies

| Ore Deposit Type | Mining Method | Typical Recovery Rate | Key Equipment |

| Pegmatite Deposit | Open-Pit Bench Mining | 85-92% | Electric Hydraulic Shovel (CAT 6040) |

| Salt Lake Deposit | Salt Field Concentration | 40-60% | Corrosion-Resistant Pump (Hastelloy C276 Material) |

| Clay-Type Ore | In-Situ Leaching | 65-75% | High-Pressure Grouting System (30MPa) |

Innovations in Salt Lake Brine Extraction

The vertical-horizontal well dual-circulation system implemented at Silver Peak in the U.S. represents a major engineering breakthrough, combining corrosion-resistant stainless steel vertical wells (1.2 m diameter) with extended radial horizontal wells (>800 m length), significantly enhancing brine pumping efficiency by 40%. Meanwhile, Chile’s Salar de Atacama employs an intelligent evaporation management system that leverages weather station networks and AI algorithms to predict NaCl crystallization points within ±2 hours, optimizing process control and operational efficiency.

Cutting-Edge Technologies

In-situ blast leaching (suitable for clay-type lithium deposits) offers promising potential for hard-to-extract resources. With carefully spaced blast holes (5–8 m apart) and optimized sulfuric acid concentrations (5–10% H₂SO₄), this method achieved a lithium recovery rate of 70% in Mexico’s Sonora project. This innovative approach not only addresses the limitations of conventional extraction but also reduces environmental impact, paving the way for commercial-scale exploitation of low-grade clay-hosted lithium deposits.

Lithium Benefication Process

The beneficiation methods for lithium ore are broadly categorized into manual ore sorting and mechanical ore sorting based on ore properties. The primary beneficiation techniques include manual sorting, flotation, chemical or combined chemical-flotation methods, pyrolytic separation, radiological separation, and particle flotation. Among these, the first three methods are most commonly employed.

Manual sorting was one of the primary methods for producing lithium concentrates both domestically and internationally during the 1950s and 1960s. However, due to its high labor intensity, low production efficiency, significant resource waste, and poor separation efficiency, it is gradually being replaced by mechanical sorting methods.

Research and application of flotation methods began earlier. Internationally, flotation was already employed in the industrial production of spodumene concentrate by the 1930s. Spodumene flotation utilizes either reverse flotation or direct flotation; lithium mica, being easily floatable, commonly employs direct flotation. China initiated lithium spodumene flotation research in the late 1950s, followed by studies on lithium mica flotation, lithium-beryllium separation, and other lithium-beryllium ores. Flotation process flowsheets for spodumene, beryl, and lithium mica were developed and applied in newly constructed lithium-beryllium processing plants.

Chemical or combined chemical-flotation methods are suitable for salt lake lithium deposits, enabling lithium salt extraction. This process involves evaporating brine in solar evaporation ponds to precipitate sodium and potassium salts, raising lithium fluoride concentration to approximately 6%. The resulting solution is then transported to processing plants, where lithium fluoride is converted into solid lithium carbonate using the soda-firing method.

Technical and Economic Comparison of Lithium Ore Beneficiation Methods

Technique | Capex ($/t) | Energy (kWh/t) | Application |

DMS | 15-20 | 3-5 | Coarse spodumene (>2mm) |

Reverse flotation | 25-30 | 8-12 | Feldspathic ores |

Magnetic-gravity | 35-40 | 10-15 | Lepidolite ores |

Technological Breakthroughs

Spodumene Flotation

- Depressant DEXTRIN-200inhibits silicates (90% efficiency)

- Microbubble generators (10-15μm) push recovery above 85%

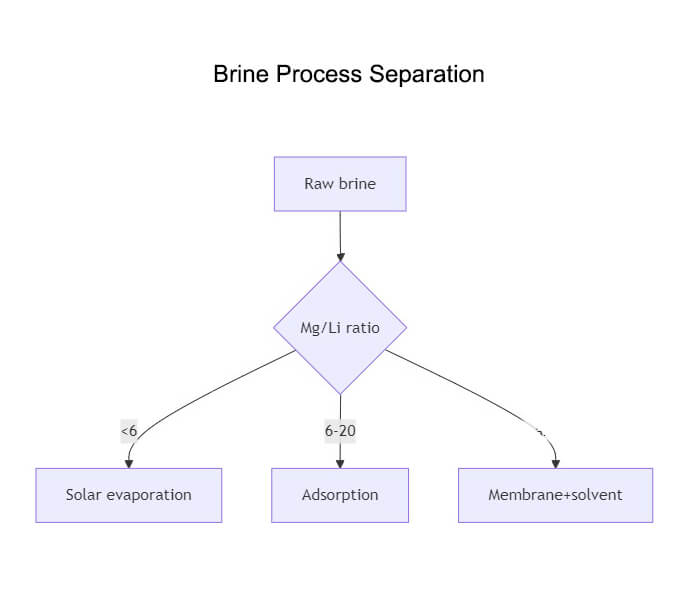

Brine Process Separation

Tailings Treatment

- H₂SO₄ leaching (200g/L) recovers 0.3-0.5% residual Li₂O

- Sensor-based sorting reduces tailings Li₂O to 0.08% (CATL standard)

Lithium metallurgy encompasses the production of compounds and the extraction of metal. For producing lithium compounds, lithium spodumene concentrate (containing 6%–6.5% Li₂O) and lithium mica concentrate (containing 4%–5% Li₂O) are processed using either the sulfuric acid or lime methods. The sulfuric acid method is suitable for lithium spodumene ore feedstock, while the lime method is suitable for lithium mica ore feedstock. Additionally, other methods for extracting lithium compounds from ore include the potassium sulfate process, chlorination roasting, and alkali leaching. Industrial production of metallic lithium employs the LiCl-KCl molten salt electrolysis process.

Conclusions

Lithium extraction faces a trilemma of technology-economics-sustainability. While Australia’s multi-stage gravity-flotation circuits consistently produce 6.0-6.5% Li₂O concentrates, China’s complex ores (e.g., Yichun Ta-Nb associations) demand selective crushing-differential flotation. Chile’s SQM developed titanium adsorbents (12mg/g capacity), revolutionizing high-Mg/Li brines.

Trends

- Digital beneficiation: XRT sorters (500 analyses/sec)

- Hybrid processes: Sulfation-roast-leach-solvent hybrid achieves 80% recovery from clays

- Tightening regulations: EU mandates 95% water reuse & 60% tailings utilization by 2026

China must prioritize Qinghai-Tibet brine purification and South China pegmatite upgrading, while establishing a full-cycle lithium database to secure battery supply chains.