During mining, construction, and manufacturing processes, large amounts of waste rock stone dust are often treated as low-value byproducts, typically discarded in landfills or piles, leading to resource waste and environmental pollution. However, through scientific sorting, deep grinding, and resource utilization technologies, stone waste can be transformed into high-value products such as construction aggregates, cement additives, or industrial fillers. This article systematically introduces the processing flow, core equipment, and real-world applications of stone waste, revealing its resource potential and key technological pathways.

What is Waste Rock Stone Dust?

Stone dust refers to granular material with a particle size of 2-10mm obtained from crushing and screening crushed stone. It is a type of waste material. It is very similar in appearance to manufactured sand, but cannot be directly used as manufactured sand. Compared with natural sand, stone dust has characteristics such as a hard texture, rough and porous surface, sharp edges, and good adhesion. It contains a large amount of stone powder with a particle size smaller than 0.16mm. Generally, there are two sources of stone dust: one is a by-product of crushed stone processing; the other is produced from the reprocessing of crushed stone.

Why Recycle and Reuse The Waste Stone Dust?

Stone dust is generally piled up as waste, and many crushed stone plants are unwilling to process it. However, waste stone dust is actually a usable resource, not entirely useless. The physical properties of stone dust are similar to sand, making it a relatively suitable substitute for sand. In urban construction, waste stone dust can directly replace river sand as an important component of concrete; it can also be processed in layers to be transformed into manufactured sand that meets standards.

Key Applications and Resource Value of Stone Waste

With proper processing, stone waste can be applied in multiple sectors:

- Construction: Replacement for natural sand/aggregates in concrete, bricks, or asphalt fillers;

- Industrial raw materials: Ground powder used in ceramics, glass, or refractory materials;

- Soil improvement: Calcium/magnesium-rich waste neutralizes acidic soils for agriculture.

- Carbon sequestration: Certain waste reacts with CO₂ to form carbonates, aiding carbon capture.

The recycling and reuse of waste stone dust can solve three problems:

- It can solve the environmental pollution problem caused by the large-scale accumulation of stone dust.

- It makes full use of social resources and alleviates resource shortages.

- Stone dust is inexpensive and can also bring considerable economic benefits.

Therefore, the recycling and reuse of waste stone dust is of great significance.

Characteristics and Challenges of Stone Waste

Stone waste is primarily generated from rock crushing, cutting, or grinding, with complex compositions often containing minerals like quartz, feldspar, and clay. Its utilization faces several challenges:

- Non-uniform particle size: Mixed coarse and fine particles require grading.

- Contaminant interference: May include soil, metals, etc., affecting downstream applications.

- Hardness variations: Some types require high grinding energy, accelerating equipment wear.

How to Process Stone Waste?

The efficient utilization of waste rock chips requires a systematic process design encompassing four stages: pretreatment, particle size control, deep processing, and resource-based applications. The following sections detail key technical points and innovation directions for each stage.

Stage 1: Pretreatment Stage – Precise Sorting and Purification

Key Objective: Remove impurities and enhance raw material homogeneity

1. Primary Sorting (Dry Method)

Screening and Grading

- Utilize multi-layer vibrating screens (apertures: 5mm/10mm/20mm) to separate different particle size fractions. Coarse particles are returned for crushing, while fine powder proceeds directly to grinding.

- Innovative Solution: Intelligent image recognition sorters (e.g., TOMRA systems) can identify and remove discolored particles containing impurities with 95% sorting accuracy.

Magnetic Separation for Iron Removal

- Permanent magnet drums (magnetic field strength ≥0.8T) eliminate metal fragments to prevent downstream equipment damage.

- Optimization Direction: Eddy current separators can concurrently sort non-ferrous metals (e.g., copper, aluminum).

2. Deep Purification (Wet Process)

Spiral Washer

Removes clay and organic impurities through hydraulic flushing; slurry water is recycled via sedimentation tanks.

Technical Upgrade

Combined high-pressure spray + ultrasonic cleaning technology removes micron-level adhered contaminants.

Stage 2: Particle Control Stage- Multi-stage Crushing and Intelligent Grinding

Core Challenge: Balancing Energy Consumption and Final Product Particle Size Distribution

1. Stepwise Crushing Process

Crushing Stage | Equipment Selection | Output Particle Size | Energy Consumption Index |

Primary Crushing | ≤50mm | 0.8-1.2 kWh/t | |

Secondary Crushing | Cone Crusher/Impact Crusher | ≤20mm | 1.5-2.0 kWh/t |

Tertiary Fine Crushing | Vertical Shaft Impact Crusher | ≤5mm | 2.5-3.5 kWh/t |

Energy-saving Techniques

Closed-circuit design (interlocking screen and crusher) to minimize over-grinding.

2. Ultrafine Grinding Process

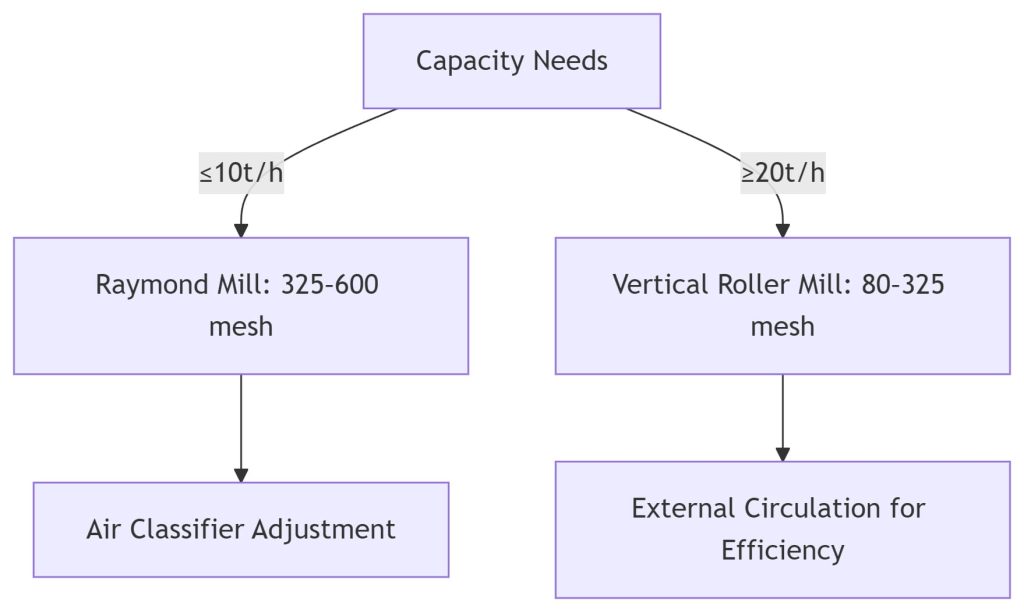

Equipment Comparison Decision Tree:

Cutting-edge Technology

Ceramic Media Vibratory Grinder (40% energy reduction, suitable for quartz sand with Mohs hardness ≥7).

Stage 3: Deep Processing Stage- Functional Modification

Key Value Enhancement: Endowing Waste Stone Chips with Special Properties

1. Surface Activation Treatment

Silane Coupling Agent Coating

Mix stone chip powder with KH-550 coupling agent (0.5-1.2% dosage) to enhance compatibility with polymer materials, suitable for plastic/rubber fillers.

Mechanical-Chemical Activation

Simultaneous grinding and surface modification in high-energy ball mills generate active sites, imparting pozzolanic properties to waste stone powder (can replace 30% clinker in cement).

2. Pore Structure Design

Foaming Agent Sintering Method

Mix stone powder with sodium bicarbonate (3-5%), then calcine at 1000°C to produce lightweight porous ceramic aggregates (density 0.6-1.2 g/cm³) for green building insulation layers.

Stage 4: Resource Application—Tailored Product Development

Application | Technical Requirements | Case Study |

Concrete Aggregate | Crush value ≤12%, silt ≤1% | Shandong project: 30% natural sand replaced |

Ceramic Body | SiO₂ ≥65%, Fe₂O₃ ≤0.5% | Guangdong factory: 80k t/year granite waste |

Soil Amendment | CaO+MgO ≥20%, particle size 2–5mm | Inner Mongolia saline soil rehab (pH↓1.2) |

Optimization Principles

- Early-Stage Sorting: Remove >90% impurities before crushing (extends grinding roller life 3x).

- Energy Cascading: Sequential “Jaw → Cone → Vertical Mill” cuts total energy by 15–25%.

- High-Value Products: Surface modification upgrades filler (¥200/t) to functional materials (¥800–1500/t).

Techno-Economic Comparison

Process Route | Capex (¥10k/t) | Opex (¥/t) | Utilization Rate |

Landfilling | 5–8 | 50–80 | 0% |

Basic Crushing (Aggregate) | 30–50 | 15–25 | 60–70% |

Ultra-Fine Grinding + Modification | 120–200 | 40–60 | 85–95% |

Deep processing offers higher ROI despite initial costs, with payback in 2–3 years via premium products. Prioritize surface modification lines for long-term competitiveness.

Key Equipment For Stone Waste Processing

Selecting key equipment for stone waste processing—such as Raymond Mills, Vertical Roller Mills (VRM), and Air Classifiers—requires careful consideration of material properties(hardness), production goals(end-use requirements), and operational costs(such as capacity).

Key Equipment Selection & Technical Adaptation

| Equipment | Advantages | Application Scenario |

| Raymond Mill | Low cost, adjustable fineness | Small/medium scale (1-10 t/h) |

| Vertical Roller Mill | 30% lower energy, high output | Large-scale (20+ t/h) |

| Air Classifier | Precise fine powder control | High-value applications (e.g., fillers) |

Summary & Industry Insights

Efficient stone waste utilization requires three breakthroughs:

- Process synergy: Seamless sorting-grinding-application integration to minimize losses;

- Equipment matching: Choose Raymond mills (flexibility) or VRMs (efficiency) based on scale;

- System design: Integrate dust control/waste heat recovery for eco-economic benefits.

With “zero-waste mining” policies advancing, stone waste recycling rates could surge from 30% to 80+, emerging as a circular economy benchmark. Enterprises must adopt full-chain technologies early to lead the green industrial transition.